Archaeological Testing of Block Fourteen's Lockley House

Colonial Williamsburg Foundation Library Research Report Series - 1674

John D. Rockefeller, Jr. Library

Colonial Williamsburg Foundation

Williamsburg, Virginia

2003

Archaeological Testing of Block

Fourteen's Lockley House

Colonial Williamsburg Foundation

Department of Archaeological Research

January 1997

Re-issued

April 2001

Management Summary

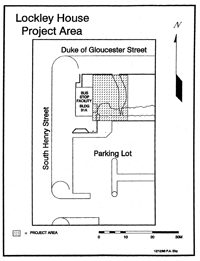

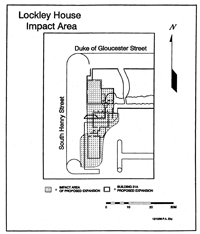

Colonial Williamsburg's Department of Archaeological Research conducted a Phase II archaeological testing of less than an acre of land around Building 31A on Block 14 in Williamsburg, Virginia. This testing was requested by Beatrix Rumford, Vice President of Special Projects. Currently owned by the Colonial Williamsburg Foundation, the property is being considered for expansion of Building 31A, and the addition of a merchandising area. The final construction plan would require construction to the south and southeast of building 31A, into the paved parking area. The area to be developed lies directly on top of and behind the remains of the John Lockley house, giving it the potential to yield more information about this structure and the lifestyles of its residents.

John Lockley, a plasterer, painter, barkeep, merchant, boarding house owner, and businessman, constructed a 38 x 20-foot house with a cellar on lot 41 by 1778. Approximately four years later, he built a 27 x 20-foot addition and two closets on the eastern end of the house, creating a 62 x 20-foot structure. By 1806, James Moir, the third owner of the property, constructed an addition off the back of the eastern end of the house, creating an L-shaped building. No longer standing by 1865, the John Lockley House was first used as a residence and became both a store and a home in the nineteenth century (Pickett 1996).

In 1950 Jimmy Knight first uncovered the foundations of this building but did not expose the entire cellar. In 1976, a section of the Lockley house cellar was salvaged under the supervision of Ivor Noel Hume before Building 31A was built. This excavation revealed four stratigraphic layers lying above a natural clay floor. There was also a feature located just outside the south wall of the structure. The feature was at the same depth as the cellar floor and is likely somehow related. Artifacts recovered from the cellar fill show that the original part of the house was destroyed around 1840 (Parker 1976). In June of 1996 Dwayne Pickett conducted a small testing project east of Building 31A in anticipation of construction. This testing revealed deep modern disturbance in the area five meters east of Building 31A.

In order to help determine the archaeological integrity of the site, four 1 x 1-meter and one .75 x .75-meter square test units were excavated on the east side of Building 31A. Two 1 x 1-meter units were set inside the foundations of the Lockley house, the three remaining units were set to the south of the Lockley house foundations.

Test Unit 1 was set inside the foundations of the Lockley house. This unit revealed the top of cellar fill, a dark gray loam with brick and mortar rubble. This cellar fill lay 10.5 inches (27 cm) below topsoil. This fill was unexcavated, but the 2.5 inch (6 cm) layer of dark gray loam which seals it dates to 1864.

Test Unit 2 was set outside the house foundations and revealed deep layers of destruction rubble containing brick, mortar, plaster, and coal below 8 inches (20 cm) of modern fill. These layers dated to post 1864 and were likely associate with the destruction of the Lockley house. The depth of this unit, 34 inches (88 cm), and its location outside the foundation of the house suggest that this test unit was placed within a very large feature ii which was filled in by the nineteenth century. When set against Jimmy Knight's architectural drawing of the Lockley house, this feature appears to be the cellar of the ca. 1806 southern addition to the house.

Test Unit 3 was placed at the southeast corner of the second phase of the Lockley house, where the nineteenth century expansion extended off the back of the house. Foundations from ca. 1782 and ca. 1806 were revealed 11.5 inches (29 cm) below modern fill. The remainder of test unit three was disturbed by one of Mr. Knight's cross trenches which outlined the foundation. Below the foundations and Mr. Knight's trenches was a gray ashy circular feature. This feature was unexcavated, but its depth 19 inches (49 cm) below modern fill and its position below the ca. 1806 foundation suggests that it dates to the eighteenth century. Jimmy Knight uncovered this feature in 1950 and identified it as a filled well.

Test Unit 4 was heavily disturbed by tree roots, was moved 19.5 inches (50 cm) to the west. It was subsequently abandoned and was not fully excavated.

Test Unit 5, a .75 x .75-meter square unit, was placed near to the parking lot, on the opposite side of the brush and trees from the other test units. This unit contained 9.5 inches (24 cm) of topsoil and 10 inches (26 cm) of soil which dated to post 1864.

The archaeological testing conducted during this project, when combined with Pickett's work, failed to uncover significant archaeological remains in the current project area. Because the foundations of two outbuildings identified by Jimmy Knight lie in the parking lot, in the project area, construction in that area should be monitored in case these features or associated layers are intact beneath the pavement. One intact eighteenth-century feature, a filled well, was identified below the foundations of the Lockley house. If plans change, any ground disturbing activities directly in or around the Lockley house should be proceeded by a full scale archaeological investigation.

Table of Contents

| Page | |

| Management Summary | ii |

| List of Figures | v |

| Introduction and Background | 1 |

| Introduction | 1 |

| Description of Project Area | 1 |

| Environmental Setting | 4 |

| Historical Background | 4 |

| European Settlement to Society (1607-1750) | 4 |

| Colony to Nation (1750-1789) | 5 |

| Early National Period (1789-1830) | 5 |

| Antebellum Period (1830-1860) | 6 |

| Civil War (1861-1865) | 6 |

| Reconstruction and Growth (1865-1917) | 6 |

| World War I to Present (1917-1996) | 7 |

| Site Specific Historical Background | 7 |

| Previous Archaeology | 8 |

| Research Design and Methods | 10 |

| Research Design | 10 |

| Field Methods | 10 |

| Laboratory Procedures | 12 |

| Results | 13 |

| Test Unit 1 | 13 |

| Test Unit 2 | 14 |

| Test Unit 3 | 15 |

| Test Unit 4 | 17 |

| Test Unit 5 | 17 |

| Conclusions | 19 |

| Recommendations | 19 |

| Current Impact Area | 19 |

| Area East of Current Impact Area | 20 |

| Bibliography | 21 |

| Appendix 1. Artifact Inventory | 23 |

| Page | |

|---|---|

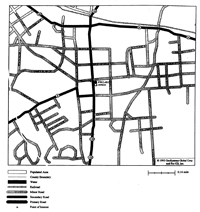

| Figure 1. Williamsburg, Virginia | 2 |

| Figure 2. Site location | 3 |

| Figure 3. Impact area | 3 |

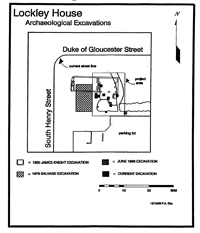

| Figure 4. Previous archaeology | 8 |

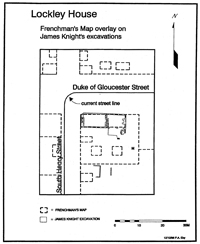

| Figure 5. Knight's excavations overlaid on the Frenchman's Map | 11 |

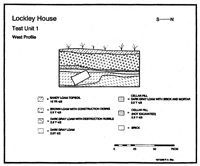

| Figure 6. Profile of Test Unit 1 | 13 |

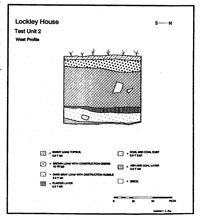

| Figure 7. Profile of Test Unit 2 | 14 |

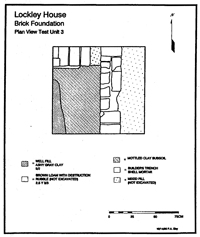

| Figure 8. Plan of Test Unit 3 | 15 |

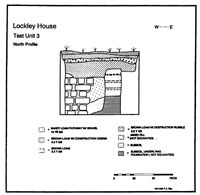

| Figure 9. North profile of Test Unit 3 | 16 |

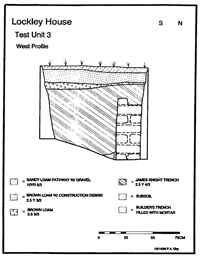

| Figure 10. West profile of Test Unit 3 | 16 |

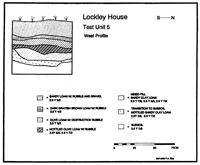

| Figure 11. Profile of Test Unit 5 | 18 |

Introduction and Background

Introduction

From September 18 to October 4, 1996, Colonial Williamsburg's Department of Archaeological Research conducted a Phase II testing of a portion of Block 14 of Williamsburg. Block 14, owned by Colonial Williamsburg, contains a ticket office and restroom, Building 31A, which is proposed for expansion. This building is located on Lot 41 where previous archaeological testing has identified a site of potential significance within and adjacent to the proposed construction area. This testing identified structural features relating to the eighteenth and nineteenth centuries. The purpose of this Phase II testing was to determine the integrity of those features and their associated layers and to assess the impact that the expansion of Building 31A would have on the archaeological resources

Historical documents reveal that Lot 41 was the site of a residential structure built around 1782 by John Lockley. Over the course of the eighteenth and nineteenth centuries, this residential site had several owners and occupants until it was razed sometime around 1864. Lot 41 also contained at least three outbuildings associated with the residence, however, the date and function of these buildings is currently unknown.

Three different archaeological projects have preceded this project. Jimmy Knight cross trenched the area in 1950 and uncovered the foundations of four buildings. Ivor Noël Hume conducted a salvage project in 1976 preceding the construction of Building 31A. In June of 1996, Dwayne Pickett tested a portion of the lot in preparation for the expansion of Building 31A. In all these cases salvage archaeology was done in areas further west of the current project area, however no testing was conducted within the present project area which includes space located within eighteenth-century yard space. Eighteenth-century yards are commonly identified by sheet midden deposits. Careful excavation and analysis of such deposits would shed light on daily life and activities during the eighteenth century.

Testing began on September 18 and took two and a half weeks to complete. Excavation was carried out under the general supervision of David Muraca, Staff Archaeologist with Colonial Williamsburg's Department of Archaeological Research. Project Archaeologist Pamela Eby supervised the field work and prepared this report. The field crew was made up of Elizabeth Gallucci and Kelly Sullivan. Laboratory processing was carried out by Gwyneth Duncan.

Description of Project Area

The project area, Lot 41, is located within Block 14, just west of the historic area of Colonial Williamsburg. This block, less than one acre, is bounded by Duke of Gloucester Street to the north, South Nassau Street to the east, Francis Street to the south, and South Henry Street to the west. The southern portion of Lot 41 is a paved parking lot. Building 31A is located in the northwest corner of the lot while the remainder of the lot is greenspace.

2 Figure 1. Williamsburg, Virginia.

Figure 1. Williamsburg, Virginia.

When this project began, plans for the expansion of Building 31A extended approximately 27 meters east of Building 31A, well into the greenspace, and covering an area slightly wider than the present building is long.

Current plans for the expansion of Building 31A were presented to the project archaeologist on October 2, 1996. These plans rotated the proposed building ninety degrees and extended the expansion south rather than east. This new orientation locates some of the impact area in the middle of the parking lot. In that this area is disturbed by paving no test excavations were located in the parking lot. Instead test units were excavated on the edge of the parking lot. The resulting test area extended ten meters east of building 31A and extended one meter beyond the length of building 31A, creating a project area of 10 x 11.5 meters (approximately 33 x 38.25 feet).

3Environmental Setting

The city of Williamsburg is located on the peninsula between the York and James Rivers. It is situated on a ridge surrounded by a series of ravines. The area now known as Block 14 is depicted on the eighteenth-century Frenchman's map as a rather level area, with ravines to the north and east, generally located along North Nassau Street and opposite the Palace Green respectively. The nearest water sources are College Creek approximately one mile to the west, and Queens Creek approximately one and one-half miles to the north. Williamsburg's climate is temperate, summers are hot and humid with average temperatures in the low nineties, winters are mild with little precipitation and average temperatures near thirty degrees Fahrenheit

The project area, located on Block 14, is currently greenspace. To the west of the project area is Building 31A, a brick ticket office and restroom. The greenspace is enclosed by a fence along its northern and eastern bounds and by an area of small trees and brush to the south. This brush area serves to separate and shield the park from the parking lot located just beyond this line of brush. Several dirt foot paths cut through the brush, providing access to the greenspace from the parking lot. One of these foot paths cuts across the project area from north to south.

Historical Background

European Settlement to Society (1607-1750)

The earliest known European settlement in the vicinity of the project area was during the third and fourth decades of the seventeenth century. In 1632 the House of Burgesses passed the "Act for Seating of the Middle Plantation" (Hening 1969) which called for the building of a palisade between the James and York Rivers, across what is today the City of Williamsburg.

Two sections of this palisade were found; one during a Phase I survey of the proposed Second Street extension (Hunter et al. 1985) and another during the private survey of the Bruton Heights School property (Muraca et al. 1992).

During the subsequent decades of the seventeenth century, the settlement of Middle Plantation grew in population and importance. By 1676 Middle Plantation was considered consequential enough for Nathaniel Bacon to launch his rebellion there (Goodwin 1959) and by 1693 important enough to be selected as the location for Virginia's first college, the College of William & Mary. By the time the General Assembly was seriously considering moving the capital there, Middle Plantation contained "a church, an ordinary, several stores, two mills, a smith's shop, a grammar school, and above all the Colledge" (reprinted in Anonymous 1930: 323-337).

In 1699 Theodorick Bland was ordered by the General Assembly to survey and lay out the new town of Williamsburg at the existing settlement of Middle Plantation. The purpose of the survey was to establish the boundaries of a new capital city for Virginia. Along with the town, two ports were included in the plan, one at Archer's Hope Creek, later known as College Creek, and another at Queen's Creek connecting the city to the York River and to Yorktown, a deep water port town established in 1691 that became Williamsburg's seaport. Land was set aside: 5

... for a Port or Landing Place in Comemoracon of the late Queen Mary of blesed Memory for the sd City of Williams Burgh on the sd Creek wch sd Port or Landing Place shall for ever hereafter be called and knowne by the Name of Queen Marys Port and the aforementioned Road or Way leading thereto shall be called Queen's Road ... .(Acts of the Virginia Assembly 1662-1702, Act XIV)

Although Williamsburg was firmly established as the capital of the Virginia Colony during the first half of the eighteenth century, it remained small, with a permanent population of about 1500. As the capital, it grew enormously, if temporarily, twice yearly, during "Publick Times" when the General Assembly was in session. In spite of the growth of Williamsburg and Yorktown as commercial and cultural centers, the majority of the population remained rural throughout this period.

Colony to Nation (1750-1789)

By the mid-eighteenth century, the capital of Virginia, the largest and most prosperous English American colony, had established itself as a viable and diverse community and cultural center, although it never came to rival New York, Boston, or Philadelphia because of the rural nature of Virginia's economy. During this period, Williamsburg had a continuously operating theatre, a college, the colonies' first asylum for the insane, a host of craft industries, and taverns. The population of the town remained small, except during the great influx of people during the "Publick Times." Leaders in the move toward revolution (such as Peyton Randolph, Patrick Henry, Thomas Jefferson, and George Washington) were members of the General Assembly, lived in Williamsburg, or frequently had reason to be there, making this period the most influential and exciting in Williamsburg's history.

During this period near Capitol Landing, a "work house" for the poor was founded in 1756 by Bruton Parish and a linen mill called "Williamsburg Manufactory" was established in 1777 (Stephenson 1951). According to advertisements in the Virginia Gazette, the landing was active during the American Revolution with merchants seeking to procure commodities for the army (McCartney 1995). A tan works with associated outbuildings and several enclosed acres was in business in March 1777 along the road between the landing and town (Virginia Gazette, Dixon and Hunter, 3/07/1777). The public gallows (44WB66), used infrequently throughout the eighteenth century, was also located along Capitol Landing Road.

Early National Period (1789-1830)

The effects of moving the capital from Williamsburg to Richmond became evident in the years following the revolution. Williamsburg and the Tidewater in general fell into economic decline as the population and influence centers moved westward. The surrounding counties continued their agrarian orientation and rotation of wheat and corn crops (Rochefoucauld 1799). The short-lived boom of wheat production declined sharply after the war in and with Europe came to an end. This was helped along by insect ravages and the poor quality of soil in over-farmed Tidewater (Brown et al. 1986).

Antebellum Period (1830-1860)

During this period, agriculture continued to be the predominant economic activity in the Williamsburg, James City, and York County area. Some improvement in the soil's ability to grow crops was initiated by Edmund Ruffin. Ruffin discovered that marl, a naturally-occurring outcrop of Miocene fossil shell, could be mixed with soil to mitigate its innate acidity, allowing better growing potential. Marl was an inexpensive and readily available commodity throughout the area. By 1840, wheat and corn production was up some 200% (Bruce 1932).

Industry in the mid-nineteenth century Williamsburg area included five dry goods stores, eight lumber yards, one tannery, two grist mills, a carriage manufactory, and a furniture shop. By 1860 there were fourteen mills in the area, 11 in James City and 3 in York County (Brown et al. 1986).

Williamsburg in 1835 consisted of 200 houses in addition to a new market house, sixteen stores, a manufactory, four mills, three tanyards, and a saddler's shop. In 1855 a new courthouse and two Baptist churches were under construction in the city (Carson 1961).

During the early nineteenth century several free black communities were established in the Williamsburg area. The most notable was Centerville, located in James City County, several miles northwest of the city. By 1850 nearly 400 free African Americans lived around Centerville, gainfully employed in agriculture and craft-related industries.

By the outbreak of the Civil War, the Williamsburg area was recovering from the economic setbacks of the late eighteenth century, both agriculturally and industrially, becoming a viable entity in Tidewater Virginia once again.

Civil War (1861-1865)

Williamsburg again became a center of activity during the first half of the Civil War as an enemy-occupied town during the Peninsula Campaign. Although no known fortifications existed within a kilometer of the project area, Fort Magruder and associated earthworks are located about three kilometers (1.8 miles) to the south.

Reconstruction and Growth (1865-1907)

The James City, York County, Williamsburg area recovered slowly from the effects of the Civil War. Agriculture was still the basis of the economy, but the lack of slave labor changed farming practices. A large population of free blacks remained in the area, serving again as laborers on farms. While other parts of the country were experiencing a rise in industrialization, this area remained strongly agrarian. Large plantations were broken up into smaller farms, some owned by the slaves that once attended them (Brown et al. 1986).

The advent of the railroad in 1881 as an efficient method of transporting both people and commodities began to help the area out of its economic slumber, but not until well into the twentieth century. Unfortunately, highways fell into disrepair, probably into a worse state than they were in during the first part of the eighteenth century. The steamship also 7 saw its rise in this period with regular stops in West Point, Williamsburg, Newport News, and Norfolk.

It should also be noted that the early preservation movement that was to become so important to the Williamsburg area in the next period, began with activities centered around the tercentenary of the establishment of Jamestown. The Association for the Preservation of Virginia Antiquities was founded in 1889, the College of William & Mary was re-opened in 1888, President Roosevelt called national attention to Jamestown in 1907, and the Reverend W.A.R. Goodwin restored Bruton Parish Church in 1907.

World War I to Present (1917-1996)

The Williamsburg area remained largely dependent economically on farming well into the twentieth century. In the late 1920s new industries were established that would forever change the economic landscape of the Williamsburg area, historic preservation and tourism. The restoration of Virginia's second capital through the efforts of W.A.R. Goodwin and John D. Rockefeller succeeded in bringing the area out of its economic rut, causing a great deal of growth in a relatively short time. Within the last 30 years, the small farm has all but disappeared from the landscape, being replaced by shopping centers, outlet malls, and housing developments. Tourism has become the major source of income in the area. Other industries in the Williamsburg area include beer manufacturing, glass making, fibers, and a winery.

Site Specific Historical Background

Block 14 was granted separately to both Thomas Jones and John Blair in 1719. There has been no explanation for this duplicate ownership, nor is there any record of buildings for either of these men at Block 14. It is not known when the next owner bought the property, but John Lockley is first known to have resided at Lot 41 in 1778. Lockley paid taxes for Lots 41 and 42 (both on Block 14) beginning in 1782 (Stephenson 1955). The Frenchman's Map, drawn ca. 1782, depicts one large dwelling with three outbuildings to the south on Lot 41. The large structure, which would have been used by John Lockley, measures 62 by 20 feet.

Lots 41 and 42 stayed in Lockley's possession until 1785 when Lockley sold them to Wyatt Coleman. Coleman owned the property until his death in 1798 when it became part of his estate and was sold to James Moir by 1801. James Moir's insurance plat issued in 1802 describes a structure unchanged from that on the Frenchman's map, measuring 20 by 60 feet; however, a policy from 1806 describes another addition to the south of the house, 18 by 24 feet in area (Stephenson 1955). The dimensions of the building described in Moir's insurance papers almost match that which Jimmy Knight uncovered and identified as the John Lockley house, the ell off the south of the Lockley house measured 14.5 x 27 feet so there is a significant discrepancy. Knight also excavated a building in the next lot to the east, Lot 42, which he identified in his plans as the James Moir house and it is possible that there is some confusion between the two structures (Knight in Colonial Williamsburg Block and Building File ca. 1950).

8Moir owned Lots 41 and 42 until 1810. Thomas Turner bought the land from Moir and held it until his own death by April 1823. Under Turner's ownership, some part of the then standing building was used as a store. Mrs. Turner owned the property from 1823 to 1838. Upon Mrs. Turner's death in 1838, Rev. Scervant Jones acquired the property and was charged taxes for it until 1858 when title was transferred to Charles C. P. Waller. Waller abandoned the property between 1861 and 1865, but paid taxes on it again in 1865 with the notation that his dwelling had been completely destroyed (Stephenson 1955).

Previous Archaeology

Cross trenching and salvage archaeological excavation have provided information regarding the structures situated on Block 14. Jimmy Knight's excavation in 1950 revealed a dwelling and several outbuildings that underwent several phases of construction. The earliest portion of the dwelling was 38 x 20 feet and had a cellar. The second phase of construction was the addition of closets to the south of both chimneys. The third phase was a large addition to the eastern end of the structure. This addition measured 27 x 20 feet and included a second cellar. A portion of the eastern wall of the earlier cellar was removed in order to gain entrance to the new cellar. At the end of this phase, the building measured 62 x 20 feet. The final phase construction was a 14.5 x 27 foot ell addition to the back of the house which contained a third cellar.

Figure 4. Previous Archaeology.

Figure 4. Previous Archaeology.

Jimmy Knight excavated using a method known as cross-trenching. This technique uses shovel trenches dug to subsoil. These trenches are a shovel's width and are set a shovel's length apart. Knight's trenches are oriented northeast to southwest. The goal of such a technique is to intersect intact foundations. Once a foundation is encountered, it is outlined, both on the inside and outside walls of the foundation in order to completely reveal the structure. Jimmy Knight used this technique at Block 14 and outlined the foundations of the John Lockley House and the remnants of three outbuilding foundations to the south, however this excavation took no heed of stratigraphy. Knight's concern was with architectural phasing which is described above.

In 1976 Colonial Williamsburg planned to install a ticket office and restroom on Block 14. Prior to this construction, a salvage archaeological excavation headed by Ivor Noel Hume was carried out in the area which would be affected by construction. The main area impacted by this construction was the original portion of the John Lockley house. The impact area extended from the middle of the western cellar south approximately three meters outside of the foundation wall. The impact area was excavated stratigraphically.

Within the cellar, four main layers of deposition were identified. Outside of the cellar archaeologists identified a large feature. This feature extended 2.75 meters (9 feet) south of the foundation wall and extended east and west across the excavation area. The feature was dug to the same depth as the cellar and shared its bottom layer of soil with that within the cellar, suggesting that both were part of the same feature for some time before the cellar walls were constructed. Ivor Noël Hume identified it as a possible brick borrow or the result of overestimating the size of the cellar (Parker 1976).

The west cellar fill has a TPQ of 1825 (Parker 1976). It is unclear then who built this first structure. It may have been John Lockley or one of the two earlier owners. Also unclear is the dating for the second and third phases of construction, although the Frenchman's Map illustrates that these phases were completed by 1782.

Earlier this summer, preliminary plans for the proposed building expansion were presented to Colonial Williamsburg's Department of Archaeological Research and a small testing project began on June 3, 1996 under the direction of Dwayne Pickett. This excavation took place in an area extending five meters east of the east wall of the ticket office. The five units which were opened revealed deep modern disturbance relating to the construction of Building 31 and intact layers with the earliest TPQ being 1820. Recommendations were made to allow construction in that area. Subsequent changes in the design of the expansion necessitate this project.

Research Design and Methods

Phase II testing has three specific goals. The first is to determine the integrity of the site. Second, to determine the significance of the archaeological record at the site. Third, to determine the research potential of the site. Cross trenching and salvage archaeology identified a solid eighteenth-century presence at the Lockley homelot and assured its significance. The primary research goal for this Phase II testing was to assess the integrity of the site's archaeological resources and thereby determine its research potential. Based on this assessment, recommendations were made for construction options on Lot 41. By excavating test units within the impact area, the site integrity was examined, recorded, and evaluated. The area under the existing parking lot was not tested because it was fairly disturbed.

Research Design

Eighteenth-century garbage disposal patterns generally consisted of either tossing waste into abandoned wells, cellars, or other pits not expressly dug for rubbish disposal or scattering it across property forming a disposal pattern known as a sheet midden.

The research design, including field methods and laboratory procedures assess the integrity of layers of soil and features which may have been created through these eighteenth-century disposal practices. Testing was restricted to the immediate area to be affected by the expansion of Building 31A.

Field Methods

Several test units were planned for excavation throughout the area which, according to the then original plan, would be impacted by the expansion of the ticket office. Shortly after testing began, the proposed expansion was relocated along a north-south rather than an east-west axis, thus changing the area scheduled to be impacted. The extension now ran into a paved parking lot. From James Knight's cross trenching in 1950, and James Parker's excavation in 1976, we knew where the John Lockley house was located. Our first test unit was placed in an area where the corner of the new building was to be placed. This unit was also located within the Lockley house foundations so that the amount of fill over the cellar could be determined.

Test Unit 1 would only be dug to the top of the cellar fill. Our goal here was simply to identify an intact layer of cellar fill and to record how deep into the ground this intact layer sat.

Test Unit 2 was placed outside the foundation line, but near to it in order to verify our identification of cellar fill. This unit and all subsequent units were to be dug to subsoil. Test Unit three was located in the area thought to be the bulkhead entrance to the east cellar.

Test Units 4 and 5 were set a good distance to the south of the foundation, with Unit five being as close as possible to the parking lot . These units were selected in hopes of identifying the remains of the outbuildings relating to the Lockley house. The Frenchman's map depicts two smaller buildings to the south of this larger dwelling. It is possible that 11 these structures depicted on the map are the same ones which Jimmy Knight uncovered in 1950. Archaeology in the this particular area could help to date these buildings as well as attribute uses to them.

A grid was created for the site using a manual transit. This grid is tied into the northeastern corner of Building 31A, and grid directions are based on the walls of this building. The site grid can be tied into a city grid from the coordinates of the northeast corner of Building 31A. All test units were given coordinates and the northwest corner was used to designate location on the site grid. All test units were excavated in natural layers and each layer was given a specific context number. Artifacts were collected from each layer and were recorded by context number. Standardized forms were used to record information specific to each context.

Four of the excavated test units were 1 x 1 meter squares while test unit five was a .75 x .75 meter square due to both its proximity to the parking lot and the line of heavy brush across the project area.

All units were dug in natural layers. All soil was passed through ¼-inch screen. All artifacts were kept save bricks, mortar, marl, shell, coal and charcoal of which only a sample was saved and the rest recorded. The crew drew profiles of the west wall of each unit in order to illustrate stratigraphy. Due to the location of the site in a public area and along a foot path, each unit was backfilled immediately after excavation and recording was completed.

Figure 5. Knight's Excavations Overlaid on the Frenchman's Map.

Figure 5. Knight's Excavations Overlaid on the Frenchman's Map.

All features were photographed in black-and-white and in color film and were drawn. A site map was drawn using existing structures and boundary lines for reference. All significant maps and drawings were digitized into AutoCAD files and are stored at the Department of Archaeological Research.

Laboratory Procedures

All artifacts were washed and were coded using ReDiscovery, a computerized coding system. Artifacts, as well as documentation, are stored at the Department of Archaeological Research.

Results

The stratigraphy in the test units varied from simple to complex. The test units dug in the grassy area had a surface of grass and sod. Test Unit 3, dug in the footpath, cut through a silty, extremely hard packed dirt path with heavy gravel inclusions. Test Units 4 and 5, located in the brush, had a surface of loosely packed loamy soil under fallen leaves and broken branches.

Test Units 1 through 3 had similar upper layers. The first layer was topsoil (or for Unit 3, a pathway) which was approximately 2.5 inches (6 cm) deep. Below this layer was a twentieth-century construction layer, associated with the construction of Building 31A. This construction layer was rather thick, ranging from 5.5 inches (14 cm) in Units two and three to 7.8 inches (20 cm) in Unit 1. In Units 1 and 2 the layer beneath this was a nineteenth-century destruction layer differentiated from the construction layer above it by a lack of pebbles and gravel. This nineteenth-century destruction layer was also present in Test Unit 3, but between it and the twentieth-century construction layer was another layer. This layer consisted of brown loam like the construction layer but lacked the rubble found either in it or the destruction layer. From this destruction layer on, the stratigraphy is unique to each unit.

Test Unit 1

In Test Unit 1 the nineteenth-century destruction layer is very thin, 1.2 inches (3 cm). Below this layer is a layer of dark gray loam similar to the destruction layer, but lacking the

Figure 6. Profile of Test Unit One.

14

same rubble. This layer is 2.5 inches (6 cm) deep and seals the cellar fill. This first layer of cellar fill, context 14EC-5, is darker than the layer which seals it and contains brick and mortar rubble. Context 14EC-5 contained unleaded clear glass, giving it a TPQ of 1864. The unit was not excavated beyond this layer to keep the cellar fill intact.

Figure 6. Profile of Test Unit One.

14

same rubble. This layer is 2.5 inches (6 cm) deep and seals the cellar fill. This first layer of cellar fill, context 14EC-5, is darker than the layer which seals it and contains brick and mortar rubble. Context 14EC-5 contained unleaded clear glass, giving it a TPQ of 1864. The unit was not excavated beyond this layer to keep the cellar fill intact.

Test Unit 2

Test Unit 2, set outside the foundation line contains the nineteenth-century destruction layer (context 14EC-8), as stated above, but the layer is much deeper than in any other unit, 18.75 inches (48 cm) deep. Below this layer is a 2.5 inch (6 cm) layer of plaster, context 14EC-9. Below this layer was a layer of coal and coal dust, 5 inches (13 cm) deep. The final layer in this unit was an ashy layer with coal. This layer sat above subsoil, a mottled orange and gray sandy clay. The bottom of this unit was 34.5 inches (88 cm) below the surface, which very likely could be the depth of the cellar. When one overlays this unit onto Jimmy Knight's plan of the Lockley house, this unit sits within the cellar of the southern extension of the house, so that the orange and gray clay which we uncovered could be the same "natural clay floor" which he describes. The bottom most layer in this unit, the coal and ash layer (context 14EC-11), has a TPQ of 1864.

Test Unit 3

Test Unit 3 was opened on top of the foundation of the Lockley house. Its location was determined in an attempt to hit the bulkhead entrance to the second phase of the house. Foundations from both the ca. 1782 expansion and the ca. 1806 expansion were revealed 11.5 inches (29 cm) below modern fill. The ca. 1782 foundation ran west to east across the northern portion of the unit and comprised at least 8 courses of brick. The builder's trench , which was only exposed 3 inches (8 cm) above the bottom of the unit, was composed solely of mortar. No artifacts were recovered from the builder's trench. The trench was sampled revealing a fill that was probably created by the oozing of wet mortar into the narrow space between the brickwork and the subsoil when the next layer of bricks was laid. This foundation was laid in English bond, with alternating courses of headers and stretchers.

The foundation for the ca. 1806 foundation ran north to sound across the unit. This foundation was only four courses deep and was set on subsoil. The bonding of this foundation was common bond, every course of headers, and the bricks were both full size and well bricks. The remainder of Test Unit 3 revealed one of Jimmy Knight's cross trenches which outlined the Lockley foundation. Artifacts from Knight's trench dated from the eighteenth to the twentieth centuries, but the TPQ of this fill would be 1950. Below Mr. Knight's trenches was a gray ashy circular feature, which Jimmy Knight identified as a filled well (Colonial Williamsburg Block and Building Files 1950). This feature was left unexcavated, but its location underneath the ca. 1806 addition suggests that it dates to the eighteenth century.

Figure 8. Plan of Test Unit Three.

Figure 8. Plan of Test Unit Three.

Figure 9. North Profile of Test Unit Three.

Figure 9. North Profile of Test Unit Three.

Figure 10. West Profile of Test Unit Three.

Figure 10. West Profile of Test Unit Three.

The foundations themselves were of some interest in their unusual construction methods. The southern expansion is unconnected to the east running foundation line, a gap of fill separates the two foundations. Architectural historian Mark Wenger studied this foundation and described the probable building sequence as follows: the eastern expansion of the building ended about a foot short of the later southern expansion. Some time after this first expansion there was further renovation of the structure. Likely a fireplace was added to the house, needing more support than a 1½ course brick foundation for support, the eastern portion of the house was partially knocked down and bricks were added to the foundation to the east, but not to the full cellar depth, rather, four courses from the top of the remaining foundation this chimney support was built directly on top of subsoil. At some later date, this renovation was demolished, and a new wall was built in its place, extended further south than the original foundation, creating an "L" off the back of the house. Such a scenario explains the rubble sitting between and the differing depths of the two brick rows.

Test Unit 4

Excavation of Test Unit 4 was abandoned before features were identified or subsoil was reached. The initial location of the unit was found to be full of large roots. Rather than cutting through these roots and risking killing the trees, test unit four was moved 19.5 inches (50 cm) west of its original location. The unit was excavated to a depth of 8.5 inches (22 cm) before it was abandoned.

Test Unit 5

Test Unit 5 was located just north of the parking lot. Below a 9.5 inch (24 cm) topsoil layer, this test unit extended an additional 10 inches (26 cm) to subsoil. Brick, mortar and charcoal inclusions were heavy toward the top of the unit, but by 4.5 inches (12 cm) below topsoil the inclusions were becoming infrequent. Clear, unleaded glass found in this unit gave it a TPQ of 1864.

18Conclusions

The Phase II testing of this portion of the Lockley property identified one eighteenth-century feature and two nineteenth century features. No intact eighteenth-century layers were identified. The paucity of eighteenth-century data is most likely due to the impact of twentieth-century activity. Construction of Building 31A disturbed soil 33 feet (10 m) away from the building and to a depth of 8 inches (20 cm). Jimmy Knight's efforts in 1950 obliterated features and layers abutting foundation walls. Further, examination of Knight's plan map of the Lockley house reveals that Knight may have excavated a great deal of the southern addition (an elevation reading is placed in the middle of this cellar with the caption "orig. clay floor") (Colonial Williamsburg Building and Block Files 1950).

Nineteenth century impact on the site was also evidenced throughout the project area. In each test unit, the bottom-most layer contained artifacts which gave that layer a TPQ of 1864. Charles P. Waller noted in his tax records for 1865 that his dwelling had been completely destroyed. The destruction and subsequent grading of this structure is evidenced in throughout the site in these deep layers. In Test Units 2 and 5, this mid nineteenth-century activity is the earliest intact layer. Test Unit 2 contained deep intact nineteenth-century destruction layers which were situated within the early nineteenth-century cellar added off the rear of the Lockley house. Test Unit 1, containing unexcavated cellar fill likely dates to this same period. Excavations in 1976 dated the fill from the earlier cellar to post 1825. The second cellar would have been filled simultaneously or subsequently.

Test Unit 3 also shows evidence of nineteenth-century occupation at the site. Foundation walls dating to the nineteenth century were uncovered in this unit. Below this foundation is a filled well which was abandoned and filled before ca. 1806. This well is the only feature identified by the Phase II excavation at this site which dates to the late eighteenth century.

A portion of the area which will be impacted by the expansion of Building 31A could not be tested because it was located beneath a paved parking lot. Overlying Jimmy Knight's architectural drawings of his 1950 excavation over the plans for the expansion of Building 31A shows that two outbuilding foundations lie within the impact area. This suggests that there may be intact eighteenth-century layers below the parking lot; however, Test Unit 5, located just north of the parking lot revealed only nineteenth-century layers to a depth of 19.5 inches (50 cm). In keeping with the stratigraphy over most of the site, it is highly probable that occupation from the nineteenth and twentieth centuries eliminated intact evidence of eighteenth-century occupation.

Recommendations

Current Impact Area

The unpaved portion of the current impact area is located just south of Building 31A. Test Unit 5, placed less than a meter away from the parking lot revealed layers dating to after 20 1864. This suggests that the soil under the parking lot will not contain intact layers associated with the eighteenth and nineteenth centuries. However, both the Frenchman's map and Jimmy Knight's excavation locate outbuildings in this area. Due to the possibility that features dating to the eighteenth century may be intact below the pavement, monitoring of the area during construction is recommended.

Area East of Current Impact Area

The intact Lockley house foundations, layers and feature found near the foundation, cellar fill, and deep stratigraphy outside the Lockley house suggest that the area to the east of Building 31A contains significant archaeological deposits which could yield valuable information about how the house and yard were used, the lifestyles of the residents, and architectural changes. One eighteenth-century feature has been identified in this area, a filled well which was built over by 1806. If current plans are altered so that the area east of building 31A is scheduled for development it should be preceded by a large-scale excavation of the area.

Bibliography

- 1930

- Speeches of Students of the College of William and Mary Delivered May 1, 1699. William and Mary Quarterly 10(2nd series):323-337.

- 1662-1702

- Pp.399-401, Act XIV (copy in Goodwin 1959)

- 1986

- Toward A Resource Protection Process: James City County, York County, City of Poquoson, and the City Of Williamsburg. Department of Archaeological Research, Colonial Williamsburg Foundation, 1986.

- 1932

- Virginia Agricultural Decline to 1860: A Fallacy. Agricultural History 6:3-13.

- 1961

- We Were There: Descriptions of Williamsburg, 1699-1859. Manuscript on file, Department of Research, The Colonial Williamsburg Foundation.

- 1949

- The Southern Colonies in the Seventeenth Century 1607-1689, Volume I, A History of the South. Louisiana State University Press and the Littlefield Fund for Southern History, University of Texas.

- 1781

- Carte des Environs de Williamsburg en Virginia on les Armes Francoise et Americaines ont Campes en Septembre 1781. Photostat on file. Special Collections, Colonial Williamsburg Foundation Library, Williamsburg, Virginia.

- 1996

- Personal Communication, Colonial Williamsburg Department of Archaeological Research, Williamsburg, Virginia.

- 1782

- Plan de la Ville et Environs de Williamsburg en Virginia, 1782. Photostat on file. Special Collections, Colonial Williamsburg Foundation Library, Williamsburg, Virginia.

- 1950

- Architectural Drawings for Block 14. Unpublished drawings on file in the Colonial Williamsburg Foundation Library Block and Building File, Williamsburg, VA.

- 1995

- Phase II Archaeological Testing of the 320 North Henry Lot. Colonial Williamsburg Department of Archaeological Research, Williamsburg, Virginia. Prepared for the Colonial Williamsburg Foundation. 22

- 1976

- Salvage Excavations at the John Lockley House Site. Unpublished report on file at the Department of Archaeological Research, Colonial Williamsburg Foundation, Williamsburg, VA.

- 1996

- Management Summary of Phase II Testing of Lot 41. Unpublished report on file at the Department of Archaeological Research, Colonial Williamsburg Foundation, Williamsburg, VA.

- 1996

- Phase I Archaeological Survey of the Northington and Municipal Center Blocks. Colonial Williamsburg Department of Archaeological Research, Williamsburg, VA. Prepared for the City of Williamsburg.

- 1799

- Travel through the United States of North America ... in the years 1795, 1796, and 1797. Vol. II, London.

- 1955

- History of Lots 41 & 42, Block 14. Research Department, Colonial Williamsburg Foundation.

- 1961

- "Block 36, Lot 212- 217 Historical Report." Originally reported in under the title "Colonial Lots 212- 217 Block 36." Colonial Williamsburg Foundation Library Research Report Series- 1620. Colonial Williamsburg Foundation Library, Williamsburg, Virginia.

- 1987

- Williamsburg quadrangle. 7.5-minute topographic series. USGS, Washington, D.C.

- 1991

- How to Apply the National Register Criteria for Evaluation. National Register Bulletin No. 15. U.S. Department of the Interior, National Park Service, Inter agency Resources Division, Washington, D.C.

- 1985

- Soil Survey of James City and York Counties and the City of Williamsburg, Virginia. U.S. Soil Conservation Service in cooperation with Virginia Polytechnic Institute and State University, Blacksburg.

- 1928

- Map of Williamsburg, Virginia: Restoration Survey. Revised 1930. Photostat on file. Special Collections, Colonial Williamsburg Foundation Library, Williamsburg, Virginia.

Appendix 1.

Artifact Inventory

Note: Inventory is printed from the Re:discovery cataloguing program used by Colonial Williamsburg, manufactured and sold by Re:discovery Software, Charlottesville, Virginia. Brief explanation of terms:

| Context No. | Arbitrary designation for a particular deposit (layer or feature), consisting of a four-digit "site/area" designation and a five-digit context designation. The site/area for this project is "14EC." |

|---|---|

| TPQ | "Date after which" the layer or feature was deposited, based on the artifact with the latest initial manufacture date. Deposits without a diagnostic artifact have the designation "NDA," or no date available. |

| Listing | The individual artifact listing includes the catalog "line designation," followed by the number of fragments or pieces, followed by the description. |

| AA | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, ANNULAR, POLYCHROME |

| AB | 1 | EARTHENWARE, RED-BOD SLIP, FRAGMENT |

| AA | 1 | PORCELAIN, CH PORCELAIN, FRAGMENT |

| AB | 1 | PORCELAIN, PORCELLANEOUS, FRAGMENT, OTHER MOLD DEC |

| AC | 1 | CERAMIC, FRAGMENT, FLOWERPOT |

| AD | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| AE | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, MOLD BLOWN, GREEN, LETTERING/NUMB, R . . . |

| AF | 1 | GLASS, FRAGMENT, WINDOW GLASS |

| AG | 1 | BAKELITE, FRAGMENT |

| AH | 1 | IRON ALLOY, NAIL, CUT, FRAGMENT |

| AI | 1 | IRON ALLOY, NAIL, 2 TO 4 IN, WIRE |

| AA | 3 | EARTHENWARE, DELFTWARE ENG, FRAGMENT |

| AC | 3 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AD | 2 | REFINED EARTHEN, PEARLWARE, FRAGMENT |

| AE | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PRINTED UNDER, BLUE |

| AF | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, SHELL EDGE, BLUE |

| AG | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, ANNULAR, GREEN |

| AH | 1 | STONEWARE, WESTERWALD, FRAGMENT, WHEEL THROWN |

| AI | 1 | STONEWARE, GERMAN STONEW, FRAGMENT, WHEEL THROWN |

| AJ | 1 | COARSE EARTHEN, COARSEWARE, FRAGMENT, FLOWERPOT, WHEEL THROWN, GREEN, POSSIBLE FRENCH |

| AK | 3 | CERAMIC, FRAGMENT, FLOWERPOT |

| AL | 2 | PORCELAIN, CH PORCELAIN, FRAGMENT |

| AM | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, STEM, 5/64 INCHES |

| AN | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, BOWL |

| AO | 2 | STONEWARE, FRAGMENT, DRAINAGE PIPE |

| AP | 1 | BRICK, BRICKETAGE |

| AQ | 1 | GLASS, CLRLESS LEAD, FRAGMENT, TUMBLER |

| AR | 1 | GLASS, CLRLESS LEAD, FRAGMENT, TABLE GLASS, MOLD BLOWN |

| AS | 1 | GLASS, CLRLESS LEAD, FRAGMENT, LAMP CHIMNEY |

| AT | 2 | GLASS, CLRLESS LEAD, FRAGMENT |

| AU | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, BEER/POP BOTTLE, OTHER MOLD DEC, MOLD BLOWN |

| AV | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLOWN |

| AW | 7 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| AX | 1 | GLASS, COLORED GLASS, FRAGMENT, BOTTLE, MOLD BLOWN, AQUA, CF. MEDICINE BOTTLE |

| AY | 1 | GLASS, COLORED GLASS, FRAGMENT, BEER/POP BOTTLE, OTHER MOLD DEC, MOLD BLOWN, GREEN, LETTERING/NUMB, 70-41... |

| AZ | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, MOLD BLOWN, GREEN, LETTERING/NUMB, ILLEGIBLE |

| BA | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, GREEN, APPLE GREEN |

| BB | 2 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| BB | 2 | REFINED EARTHEN, CREAMWARE, FRAGMENT, PRESS MOLDED |

| BC | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, OTHER COLOR, SMOKEY TOPAZ |

| BD | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, WHITE |

| BE | 2 | GLASS, COLORED GLASS, FRAGMENT, BEER/POP BOTTLE, OTHER MOLD DEC, MOLD BLOWN, AMBER |

| 25 | ||

| BF | 3 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AMBER |

| BG | 6 | GLASS, FRAGMENT, WINE BOTTLE |

| BH | 7 | GLASS, FRAGMENT, WINDOW GLASS |

| BI | 1 | BAKELITE, FRAGMENT |

| BJ | 2 | OTHER SYNTHETIC, FRAGMENT, BLACK, SUPPLE VINYL OR RUBBER |

| BK | 1 | BONE, FRAGMENT, POLISHED BONE FRAGMENT |

| BL | 1 | BONE, FAUNAL SPECIMEN |

| BM | 4 | SHELL, SHELL |

| BN | 2 | BRICK, BRICKETAGE |

| BO | 3 | MORTAR, CEMENT |

| BP | 5 | SHELL, MORTAR |

| BQ | 2 | IRON ALLOY, NAIL, LESS THAN 2 IN, WROUGHT/FORGED |

| BR | 1 | IRON ALLOY, NAIL, 2 TO 4 IN, WROUGHT/FORGED |

| BS | 1 | IRON ALLOY, NAIL, 2 TO 4 IN, MACHINE-MADE |

| BT | 3 | IRON ALLOY, NAIL, LESS THAN 2 IN, MACHINE-MADE |

| BU | 1 | IRON ALLOY, NAIL, MACHINE-MADE, FRAGMENT |

| BV | 4 | IRON ALLOY, NAIL, 2 TO 4 IN, WIRE |

| BW | 2 | IRON ALLOY, NAIL, LESS THAN 2 IN, WIRE |

| BX | 2 | GALVAN METAL, NAIL, LESS THAN 2 IN, WIRE |

| BY | 2 | IRON ALLOY, NAIL, FRAGMENT |

| BZ | 1 | IRON ALLOY, BOLT, LESS THAN 2 IN |

| CA | 3 | IRON ALLOY, CAN KEY, MACHINE-MADE, SARDINE CAN KEY FRAGMENTS |

| CB | 2 | IRON ALLOY, WIRE |

| CC | 1 | ALUMINUM, CAN CLOSURE, MACHINE-MADE |

| CD | 2 | IRON ALLOY, UNID HARDWARE |

| CE | 1 | QUARTZITE, DEBITAGE, SEC/THIN FLAKE |

| CF | 1 | QUARTZITE, BIFACE, FRAGMENT |

| AA | 1 | EARTHENWARE, DELFTWARE ENG, FRAGMENT, PAINT OVER/UNDR, BLUE |

| AB | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PRESS MOLDED |

| AC | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT |

| AD | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, STEM, 4/64 INCHES |

| AE | 1 | GLASS, FRAGMENT, WINE BOTTLE |

| AF | 1 | GLASS, CLRLESS LEAD, FRAGMENT, CONTAINER |

| AG | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| AH | 2 | GLASS, FRAGMENT, WINDOW GLASS |

| AI | 4 | MORTAR, CEMENT |

| AJ | 1 | IRON ALLOY, NAIL, 2 TO 4 IN, CUT |

| AK | 1 | IRON ALLOY, NAIL, LESS THAN 2 IN, WIRE |

| AL | 1 | IRON ALLOY, NAIL, LESS THAN 2 IN, MANF. TECH. UNKNOWN |

| AA | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PRINTED UNDER, BLUE |

| AB | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, OTHER MOLD DEC, PRESS MOLDED |

| AC | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRESS MOLDED |

| AD | 3 | GLASS, FRAGMENT, WINE BOTTLE |

| AE | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| AF | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLOWN, LETTERING/NUMB, M OR W |

| AG | 3 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER |

| AH | 6 | GLASS, FRAGMENT, WINDOW GLASS |

| AI | 2 | BONE, FAUNAL SPECIMEN |

| AJ | 4 | LIMESTONE, PLASTER |

| 26 | ||

| AK | 1 | MORTAR, CEMENT |

| AL | 2 | IRON ALLOY, NAIL, 2 TO 4 IN, CUT |

| AM | 2 | IRON ALLOY, NAIL, LESS THAN 2 IN, CUT |

| AA | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AB | 3 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PRINTED UNDER, BLUE |

| AC | 3 | REFINED EARTHEN, WHITEWARE, FRAGMENT, UNDECORATED |

| AD | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRINTED UNDER, PRESS MOLDED, BLUE |

| AE | 1 | REFINED EARTHEN, BENNINGTON, FRAGMENT, PRESS MOLDED |

| AF | 1 | STONEWARE, AMER BLUE/GREY, FRAGMENT, WHEEL THROWN |

| AG | 1 | STONEWARE, AMER STONEWARE, FRAGMENT, ALBANY SLIP, WHEEL THROWN |

| AH | 1 | STONEWARE, AMER BROWN, FRAGMENT, WHEEL THROWN |

| AI | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, STEM, 4/64 INCHES |

| AJ | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, STEM, 5/64 INCHES |

| AK | 2 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| AL | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, OTHER MOLD DEC, MOLD BLOWN |

| AM | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLOWN, LETTERING/NUMB, ...T, LEIGHTON'S PATENT |

| AN | 3 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AMBER |

| AO | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, GREEN |

| AP | 4 | GLASS, FRAGMENT, WINE BOTTLE |

| AQ | 1 | GLASS, FRAGMENT, BURNED |

| AR | 35 | GLASS, FRAGMENT, WINDOW GLASS |

| AS | 4 | BONE, FAUNAL SPECIMEN |

| AT | 3 | SHELL, SHELL |

| AU | 5 | PLASTER, PLASTER, SHELL |

| AV | 7 | IRON ALLOY, NAIL, LESS THAN 2 IN, WROUGHT/FORGED |

| AW | 1 | IRON ALLOY, NAIL, WROUGHT/FORGED, FRAGMENT |

| AX | 1 | IRON ALLOY, NAIL, 2 TO 4 IN, WIRE |

| AY | 1 | COPPER ALLOY, UNID HARDWARE, THIN FOLDED SHEET |

| AZ | 1 | PORCELAIN, PORCELLANEOUS, FRAGMENT, BURNED |

| AA | 1 | COARSE EARTHEN, N DEVON, GRAV, FRAGMENT, WHEEL THROWN |

| AB | 1 | GLASS, FRAGMENT, WINE BOTTLE |

| AC | 1 | GLASS, CLRLESS LEAD, FRAGMENT, CONTAINER, OTHER MOLD DEC, MOLD BLOWN |

| AD | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| AE | 2 | GLASS, FRAGMENT, WINDOW GLASS |

| AF | 1 | SHELL, SHELL |

| AG | 1 | COAL, COAL |

| AH | 1 | IRON ALLOY, NAIL, LESS THAN 2 IN, WROUGHT/FORGED |

| AA | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AB | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PRINTED UNDER, PRESS MOLDED, BLUE |

| AC | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PAINTED UNDER, POLYCHROME |

| AD | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT |

| AE | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PAINTED UNDER, BLUE |

| AF | 3 | STONEWARE, AMER BLUE/GREY, FRAGMENT, WHEEL THROWN |

| AG | 1 | REFINED EARTHEN, BENNINGTON, FRAGMENT |

| 27 | ||

| AH | 1 | PORCELAIN, CH PORCELAIN, FRAGMENT |

| AI | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, BOWL |

| AJ | 5 | GLASS, FRAGMENT, WINE BOTTLE |

| AK | 1 | GLASS, CLRLESS NON-LD, FRAGMENT |

| AL | 2 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLOWN |

| AM | 2 | GLASS, CLRLESS NON-LD, FRAGMENT, BEER/POP BOTTLE, OTHER MOLD DEC, MOLD BLOWN |

| AN | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, OTHER MOLD DEC, MOLD BLOWN |

| AO | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| AP | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, GREEN |

| AQ | 6 | GLASS, FRAGMENT, WINDOW GLASS |

| AR | 1 | OTHER SYNTHETIC, FRAGMENT, GOLF BALL |

| AS | 1 | SLATE, SLATE, ROOFING |

| AT | 4 | BONE, FAUNAL SPECIMEN |

| AU | 2 | IRON ALLOY, NAIL, 2 TO 4 IN, CUT |

| AV | 1 | IRON ALLOY, NAIL, LESS THAN 2 IN, CUT |

| AW | 2 | IRON ALLOY, NAIL, CUT, FRAGMENT |

| AX | 2 | IRON ALLOY, NAIL, FRAGMENT |

| AY | 1 | IRON ALLOY, SPIKE, CUT, 5 INCHES |

| AZ | 1 | IRON ALLOY, OTHER HARDWARE |

| AA | 2 | EARTHENWARE, DELFTWARE ENG, FRAGMENT, PAINTED UNDER, WHEEL THROWN, BLUE |

| AB | 2 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AC | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT, PRESS MOLDED |

| AD | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PRESS MOLDED |

| AE | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PRINTED UNDER, BLUE |

| AF | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PAINTED UNDER, BLUE |

| AG | 1 | REFINED EARTHEN, BENNINGTON, FRAGMENT, PRESS MOLDED |

| AH | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRESS MOLDED |

| AI | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT |

| AJ | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRINTED UNDER, BLUE |

| AK | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRINTED UNDER, POLYCHROME |

| AL | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PAINTED UNDER, POLYCHROME |

| AM | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, SPONGED, POLYCHROME |

| AN | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, ANNULAR, POLYCHROME |

| AO | 2 | REFINED EARTHEN, IRONST/WH GRAN, FRAGMENT |

| AP | 1 | REFINED EARTHEN, IRONST/WH GRAN, FRAGMENT, PRESS MOLDED |

| AQ | 4 | REFINED EARTHEN, YELLOW WARE, FRAGMENT |

| AR | 1 | STONEWARE, WH SALT-GLAZED, FRAGMENT |

| AS | 2 | PORCELAIN, CH PORCELAIN, FRAGMENT |

| AT | 1 | PORCELAIN, CH PORCELAIN, FRAGMENT, PAINTED UNDER, BLUE |

| AU | 1 | PORCELAIN, ENG BONE CHINA, FRAGMENT |

| AV | 1 | PORCELAIN, PORCELLANEOUS, FRAGMENT |

| AW | 1 | COARSE EARTHEN, BK-GZ REDWARE, FRAGMENT, OTHER MOLD DEC |

| AX | 1 | COARSE EARTHEN, COARSEWARE, FRAGMENT, FLOWERPOT, WHEEL THROWN |

| AY | 1 | STONEWARE, AMER BLUE/GREY, FRAGMENT, WHEEL THROWN |

| AZ | 1 | STONEWARE, WESTERWALD, FRAGMENT, WHEEL THROWN |

| BA | 2 | STONEWARE, AMER BROWN, FRAGMENT, WHEEL THROWN |

| BB | 2 | CERAMIC, FRAGMENT, DRAINAGE PIPE |

| 28 | ||

| BC | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, STEM, 4/64 INCHES |

| BD | 1 | GLASS, COLORED GLASS, BUTTON, OTHER MOLD DEC, GREEN |

| BE | 1 | GLASS, COLORED GLASS, BUTTON, WHITE |

| BF | 2 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, WHITE |

| BG | 1 | BONE, BUTTON |

| BH | 20 | BONE, FAUNAL SPECIMEN |

| BI | 1 | COARSE EARTHEN, BRICKETAGE, OTHER MOLD DEC |

| BJ | 1 | SHELL, MARL |

| BK | 2 | PLASTER, PLASTER |

| BL | 1 | OTHER ORGANIC, FRAGMENT, CRINOID STEM (FOSSILIZED MARINE PLANT) |

| BM | 2 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, OTHER MOLD DEC, MOLD BLOWN, AQUA |

| BN | 2 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, MOLD BLOWN, AQUA |

| BO | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, MACHINE-MADE, AQUA |

| BP | 10 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| BQ | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, EMPONTILLED, AQUA |

| BR | 2 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, MOLD BLOWN, AQUA, POSSIBLE FRENCH CASE BOTTLE |

| BS | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, MOLD BLOWN, AQUA, LETTERING/NUMB, ILLEGIBLE |

| BT | 3 | GLASS, MANG SOLARIZED, FRAGMENT, CONTAINER |

| BU | 2 | GLASS, MANG SOLARIZED, FRAGMENT, CONTAINER, OTHER MOLD DEC, MOLD BLOWN |

| BV | 1 | GLASS, MANG SOLARIZED, FRAGMENT, CONTAINER, MOLD BLOWN, LETTERING/NUMB, ...EW... |

| BW | 1 | GLASS, MANG SOLARIZED, FRAGMENT, JAR, MOLD BLOWN |

| BX | 1 | GLASS, MANG SOLARIZED, FRAGMENT, CONTAINER, MOLD BLOWN |

| BY | 3 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, OTHER COLOR, APPLE GREEN |

| BZ | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, BROWN |

| CA | 1 | GLASS, CLRLESS LEAD, FRAGMENT, TUMBLER, OTHER MOLD DEC, PRESS MOLDED, PANELED |

| CB | 1 | GLASS, CLRLESS LEAD, FRAGMENT, TABLE GLASS, MOLD BLOWN, LARGE BASE WITH POSSIBLE GROUND EMPONTIL |

| CC | 5 | GLASS, CLRLESS LEAD, FRAGMENT, CONTAINER |

| CD | 5 | GLASS, CLRLESS LEAD, FRAGMENT, TABLE GLASS |

| CE | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, TABLE GLASS |

| CF | 14 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| CG | 2 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLOWN |

| CH | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, BOTTLE, MOLD BLOWN, NECK |

| CI | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLOWN, LETTERING/NUMB, ...RA... |

| CJ | 21 | GLASS, FRAGMENT, WINE BOTTLE |

| CK | 1 | GLASS, FRAGMENT, WINE BOTTLE, HAND TOOLED FIN |

| CL | 1 | GLASS, FRAGMENT, WINE BOTTLE, BURNED |

| CM | 153 | GLASS, FRAGMENT, WINDOW GLASS |

| CN | 1 | IRON ALLOY, KEY, CAST |

| CO | 1 | COPPER ALLOY, LOCK/LOCK PART, CAST |

| CP | 4 | IRON ALLOY, WIRE, DRAWN, FRAGMENT |

| CQ | 9 | IRON ALLOY, NAIL, LESS THAN 2 IN, WROUGHT/FORGED |

| CR | 21 | IRON ALLOY, NAIL, LESS THAN 2 IN, CUT |

| CS | 11 | IRON ALLOY, NAIL, LESS THAN 2 IN, WIRE |

| CT | 4 | IRON ALLOY, NAIL, 2 TO 4 IN, CUT |

| CU | 15 | IRON ALLOY, NAIL, 2 TO 4 IN, WIRE |

| CV | 6 | IRON ALLOY, NAIL, WROUGHT/FORGED, FRAGMENT |

| CW | 12 | IRON ALLOY, NAIL, CUT, FRAGMENT |

| 29 | ||

| CX | 5 | IRON ALLOY, NAIL, WIRE, FRAGMENT |

| CY | 3 | IRON ALLOY, NAIL, TACK, WIRE |

| CZ | 1 | IRON ALLOY, NAIL, TACK, CUT |

| DA | 3 | IRON ALLOY, UNID HARDWARE |

| DB | 1 | OTHER INORGANIC, SLAG/CLINKER |

| AA | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRESS MOLDED |

| AB | 1 | REFINED EARTHEN, YELLOW WARE, FRAGMENT |

| AC | 1 | COARSE EARTHEN, BK-GZ REDWARE, FRAGMENT |

| AD | 1 | PORCELAIN, ENG BONE CHINA, FRAGMENT, PRESS MOLDED |

| AE | 2 | GLASS, CLRLESS LEAD, FRAGMENT, TABLE GLASS, MOLD BLOWN |

| AF | 13 | GLASS, FRAGMENT, WINDOW GLASS |

| AG | 1 | BONE, FAUNAL SPECIMEN, RIB FRAGMENT, POSSIBLY WORKED |

| AH | 1 | LIMESTONE, PLASTER |

| AI | 1 | IRON ALLOY, NAIL, LESS THAN 2 IN, CUT |

| AJ | 1 | IRON ALLOY, UNID HARDWARE |

| AA | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRESS MOLDED |

| AB | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT |

| AC | 1 | REFINED EARTHEN, YELLOW WARE, FRAGMENT, PRESS MOLDED |

| AD | 16 | GLASS, FRAGMENT, WINE BOTTLE |

| AE | 1 | GLASS, CLRLESS LEAD, FRAGMENT, TABLE GLASS |

| AF | 1 | GLASS, CLRLESS LEAD, FRAGMENT, CONTAINER, MOLD BLOWN |

| AG | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, BOTTLE, OTHER MOLD DEC, MOLD BLN/EMPONT, BASE |

| AH | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, BOTTLE, MOLD BLOWN, BASE |

| AI | 2 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| AJ | 6 | GLASS, FRAGMENT, WINDOW GLASS |

| AK | 1 | BONE, BUTTON |

| AL | 1 | BONE, FAUNAL SPECIMEN |

| AM | 8 | WOOD, FRAGMENT |

| AN | 1 | COPPER ALLOY, OTHER HARDWARE, MACHINE-MADE, THREADED CAP |

| AO | 1 | IRON ALLOY, NAIL, 2 TO 4 IN, CUT |

| AP | 1 | IRON ALLOY, UNID HARDWARE |

| AA | 1 | EARTHENWARE, DELFTWARE ENG, FRAGMENT |

| AB | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT, OTHER MOLD DEC, PRESS MOLDED |

| AC | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AD | 3 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PRESS MOLDED |

| AE | 2 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PAINTED UNDER, POLYCHROME |

| AF | 2 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PAINTED UNDER, BLUE |

| AG | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PRINTED UNDER, BLUE |

| AH | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT |

| AI | 1 | STONEWARE, AMER BROWN, FRAGMENT, WHEEL THROWN |

| AJ | 1 | STONEWARE, NOTTINGHAM SW, FRAGMENT, WHEEL THROWN |

| AK | 1 | PORCELAIN, CH PORCELAIN, FRAGMENT, PAINTED UNDER, BLUE |

| AL | 4 | GLASS, FRAGMENT, WINE BOTTLE |

| AM | 1 | GLASS, CLRLESS LEAD, FRAGMENT, CONTAINER |

| AN | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLN/EMPONT |

| AO | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| 30 | ||

| AP | 45 | GLASS, FRAGMENT, WINDOW GLASS |

| AQ | 2 | BONE, FAUNAL SPECIMEN |

| AR | 1 | SHELL, MARL |

| AS | 2 | IRON ALLOY, NAIL, LESS THAN 2 IN, WROUGHT/FORGED |

| AU | 2 | IRON ALLOY, NAIL, FRAGMENT |

| AV | 3 | IRON ALLOY, UNID HARDWARE |

| AA | 2 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AB | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PAINTED UNDER, BLUE |

| AC | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT |

| AD | 3 | STONEWARE, FULHAM SW, FRAGMENT, WHEEL THROWN |

| AE | 1 | PORCELAIN, CH PORCELAIN, FRAGMENT |

| AF | 3 | GLASS, FRAGMENT, WINE BOTTLE |

| AG | 1 | GLASS, FRAGMENT, WINE BOTTLE, LIPPING TOOL |

| AH | 3 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| AI | 2 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLOWN |

| AJ | 2 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| AK | 1 | GLASS, COLORED GLASS, FRAGMENT, BEER/POP BOTTLE, MOLD BLOWN, BROWN |

| AL | 1 | GLASS, COLORED GLASS, FRAGMENT, BEER/POP BOTTLE, MOLD BLOWN, AMBER |

| AM | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AMBER |

| AN | 5 | GLASS, FRAGMENT, WINDOW GLASS |

| AO | 1 | PLASTIC, FRAGMENT |

| AP | 1 | IRON ALLOY, NAIL, FRAGMENT |

| AQ | 1 | OTHER SYNTHETIC, OTHER HARDWARE, MACHINE-MADE, CHAMPION SPARK PLUG |

| AR | 1 | QUARTZITE, DEBITAGE, SEC/THIN FLAKE, NON-CORTICAL |

| AA | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT, PRESS MOLDED |

| AB | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, INDETERMINATE, BLUE |

| AC | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT |

| AD | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, SLIP DECORATED, BLUE, SURF DEGRADED |

| AE | 2 | COARSE EARTHEN, FRAGMENT, FLOWERPOT |

| AF | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, BOWL |

| AG | 6 | GLASS, FRAGMENT, WINE BOTTLE |

| AH | 1 | GLASS, CLRLESS LEAD, FRAGMENT, CONTAINER, PRESSED |

| AI | 4 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| AJ | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLOWN |

| AK | 4 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| AL | 1 | GLASS, COLORED GLASS, FRAGMENT, BEER/POP BOTTLE, MOLD BLOWN, AMBER |

| AM | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, PRESSED, WHITE |

| AN | 2 | GLASS, FRAGMENT, WINDOW GLASS |

| AO | 1 | PLASTER, PLASTER, LIME |

| AP | 1 | COAL, COAL |

| AQ | 1 | OTHER INORGANIC, SLAG/CLINKER |

| AR | 1 | IRON ALLOY, NAIL, LESS THAN 2 IN, WROUGHT/FORGED |

| AS | 1 | IRON ALLOY, OTHER HARDWARE, FLAT, MACHINE-MADE |

| AA | 1 | EARTHENWARE, DELFTWARE ENG, FRAGMENT, PAINTED UNDER, BLUE |

| AB | 3 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AC | 5 | REFINED EARTHEN, CREAMWARE, FRAGMENT, PRESS MOLDED |

| 31 | ||

| AD | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT, OTHER MOLD DEC, PAINTED UNDER, PRESS MOLDED, GREEN |

| AE | 2 | REFINED EARTHEN, PEARLWARE, FRAGMENT |

| AF | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, SHELL EDGE, PAINTED UNDER, PRESS MOLDED, BLUE |

| AG | 2 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRESS MOLDED |

| AH | 4 | REFINED EARTHEN, WHITEWARE, FRAGMENT |

| AI | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRINTED UNDER, BLUE |

| AJ | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRESS MOLDED, SURF DEGRADED |

| AK | 1 | EARTHENWARE, DELFTWARE ENG, FRAGMENT, PRESS MOLDED, YELLOW |

| AL | 1 | COARSE EARTHEN, BK-GZ REDWARE, FRAGMENT, WHEEL THROWN |

| AM | 1 | STONEWARE, WESTERWALD, FRAGMENT, WHEEL THROWN |

| AN | 1 | STONEWARE, WH SALT-GLAZED, FRAGMENT |

| AO | 1 | STONEWARE, AMER BROWN, FRAGMENT, WHEEL THROWN, UNDERFIRED |

| AP | 2 | PORCELAIN, CH PORCELAIN, FRAGMENT, PAINTED UNDER, BLUE |

| AR | 1 | PORCELAIN, CH PORCELAIN, FRAGMENT |

| AS | 1 | PORCELAIN, PORCELLANEOUS, FRAGMENT |

| AT | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, STEM, 5/64 INCHES |

| AU | 6 | CERAMIC, FRAGMENT, DRAINAGE PIPE |

| AV | 20 | GLASS, FRAGMENT, WINE BOTTLE |

| AW | 1 | GLASS, CLRLESS LEAD, FRAGMENT, PRESSED |

| AX | 3 | GLASS, CLRLESS LEAD, FRAGMENT, UNIDENTIFIED |

| AY | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, TABLE GLASS, MOLD BLOWN |

| AZ | 3 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, OTHER MOLD DEC |

| BA | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLOWN |

| BB | 3 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| BC | 7 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| BD | 1 | GLASS, COLORED GLASS, FRAGMENT, BOTTLE, MOLD BLOWN, AQUA |

| BE | 2 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, GREEN |

| BF | 1 | GLASS, COLORED GLASS, FRAGMENT, AQUA, BURNED |

| BG | 37 | GLASS, FRAGMENT, WINDOW GLASS |

| BH | 8 | BONE, FAUNAL SPECIMEN |

| BI | 1 | PLASTER, PLASTER, SHELL |

| BJ | 3 | IRON ALLOY, NAIL, 2 TO 4 IN, WROUGHT/FORGED |

| BK | 2 | IRON ALLOY, NAIL, LESS THAN 2 IN, WROUGHT/FORGED |

| BL | 2 | IRON ALLOY, NAIL, LESS THAN 2 IN, CUT |

| BM | 2 | IRON ALLOY, NAIL, LESS THAN 2 IN, WIRE |

| BN | 13 | IRON ALLOY, NAIL, WROUGHT/FORGED, FRAGMENT |

| BO | 1 | IRON ALLOY, UNID HARDWARE, WROUGHT/FORGED |

| AA | 4 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AB | 2 | REFINED EARTHEN, CREAMWARE, FRAGMENT, PRESS MOLDED |

| AC | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT, FEATHER EDGE, PAINTED UNDER, PRESS MOLDED, GREEN |

| AD | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PAINTED UNDER, BLUE |

| AE | 2 | REFINED EARTHEN, PEARLWARE, FRAGMENT, SHELL EDGE, PAINTED UNDER, PRESS MOLDED, BLUE |

| AG | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, SURF DEGRADED |

| AH | 2 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRINTED UNDER, BLUE |

| AI | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT |

| AJ | 1 | COARSE EARTHEN, YORKTOWN-TYPE, FRAGMENT, WHEEL THROWN, MISSING GLAZE |

| 32 | ||

| AK | 1 | STONEWARE, WH SALT-GLAZED, FRAGMENT, WHEEL THROWN |

| AL | 1 | STONEWARE, AMER BLUE/GREY, FRAGMENT, WHEEL THROWN |

| AM | 1 | STONEWARE, FULHAM SW, FRAGMENT, WHEEL THROWN |

| AN | 2 | PORCELAIN, PORCELLANEOUS, FRAGMENT |

| AO | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, STEM, 4/64 INCHES |

| AP | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, STEM, 5/64 INCHES |

| AQ | 1 | CERAMIC, FRAGMENT, DRAINAGE PIPE |

| AR | 1 | BRICK, BRICKETAGE |

| AS | 12 | GLASS, FRAGMENT, WINE BOTTLE |

| AU | 1 | GLASS, FRAGMENT, WINE BOTTLE, BASE, FRENCH |

| AV | 1 | GLASS, CLRLESS LEAD, FRAGMENT, CONTAINER |

| AW | 1 | GLASS, CLRLESS LEAD, FRAGMENT, CONTAINER, BEADED, PRESSED |

| AX | 2 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| AY | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, BOTTLE, MOLD BLOWN, LETTERING/NUMB, ...RAL L...DS SA...-USE...OTT |

| AZ | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| BA | 23 | GLASS, FRAGMENT, WINDOW GLASS |

| BB | 2 | COAL, COAL |

| BC | 4 | BONE, FAUNAL SPECIMEN |

| BD | 2 | IRON ALLOY, NAIL, 2 TO 4 IN, WROUGHT/FORGED |

| BE | 3 | IRON ALLOY, NAIL, LESS THAN 2 IN, WROUGHT/FORGED |

| BF | 1 | IRON ALLOY, NAIL, 2 TO 4 IN, CUT |

| BG | 1 | IRON ALLOY, NAIL, LESS THAN 2 IN, CUT |

| BH | 1 | IRON ALLOY, NAIL, WROUGHT/FORGED, FRAGMENT |

| BI | 1 | IRON ALLOY, SCREW, MACHINE-MADE |

| BJ | 3 | IRON ALLOY, UNID HARDWARE |

| AA | 1 | EARTHENWARE, DELFTWARE ENG, FRAGMENT, WHEEL THROWN |

| AB | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT, FEATHER EDGE, PRESS MOLDED |

| AC | 3 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AD | 1 | REFINED EARTHEN, PEARLWARE, FRAGMENT, PRINTED UNDER, BLUE |

| AE | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRINTED UNDER, BLUE |

| AF | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, MAKER'S MARK, MADE . . . |

| AG | 5 | REFINED EARTHEN, WHITEWARE, FRAGMENT, PRESS MOLDED |

| AH | 1 | STONEWARE, NOTTINGHAM SW, FRAGMENT, WHEEL THROWN |

| AI | 1 | STONEWARE, WH SALT-GLAZED, FRAGMENT, INCISED, WHEEL THROWN |

| AJ | 3 | STONEWARE, WH SALT-GLAZED, FRAGMENT, WHEEL THROWN |

| AK | 2 | PORCELAIN, PORCELLANEOUS, FRAGMENT |

| AL | 1 | CERAMIC, FRAGMENT, DRAINAGE PIPE |

| AM | 6 | GLASS, FRAGMENT, WINE BOTTLE |

| AN | 1 | GLASS, CLRLESS LEAD, FRAGMENT, CONTAINER |

| AO | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, BOTTLE, MOLD BLOWN, LETTERING/NUMB, ...-2... |

| AP | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, BEER/POP BOTTLE, MOLD BLOWN |

| AQ | 15 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| AR | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, BEADED |

| AS | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, OTHER MOLD DEC |

| AT | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, OTHER MOLD DEC, PRESSED, PINEAPPLE MOTIF |

| AU | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, ROD |

| AV | 3 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, AQUA |

| 33 | ||

| AW | 2 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, GREEN |

| AX | 22 | GLASS, FRAGMENT, WINDOW GLASS |

| AY | 1 | PLASTIC, FRAGMENT, STRAW-LIKE, NOT HOLLOW |

| AZ | 1 | PLASTIC, FRAGMENT, WIRE INSULATION |

| BA | 4 | BONE, FAUNAL SPECIMEN |

| BB | 3 | SHELL, SHELL |

| BC | 4 | IRON ALLOY, NAIL, LESS THAN 2 IN, WIRE |

| BD | 2 | IRON ALLOY, NAIL, LESS THAN 2 IN, CUT |

| BE | 5 | IRON ALLOY, SCREW, LESS THAN 2 IN, MACHINE-MADE |

| BF | 1 | IRON ALLOY, SCREW, LESS THAN 2 IN, MACHINE-MADE, WITH METAL PLATE ATTACHED |

| BG | 1 | ALUMINUM, FRAGMENT, MACHINE-MADE, PULL-TAB |

| BH | 1 | COPPER ALLOY, OTHER HARDWARE, MACHINE-MADE, AND RUBBER; AUTOMOBILE ROTOR |

| BI | 1 | COPPER ALLOY, TOKEN, MACHINE-MADE, OR ONE-CENT PIECE |

| BJ | 1 | COPPER ALLOY, COIN, MACHINE-MADE, LETTERING/NUMB, 1967, LINCOLN CENT |

| BK | 1 | COPPER ALLOY, WIRE, MACHINE-MADE |

| BL | 1 | ALUMINUM, UNID HARDWARE |

| BM | 4 | IRON ALLOY, UNID HARDWARE |

| AA | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AB | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT |

| AC | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, BURNED |

| AD | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, OTHER MOLD DEC, PRESS MOLDED |

| AE | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT, ANNULAR, POLYCHROME |

| AF | 1 | STONEWARE, AMER BROWN, FRAGMENT, ALBANY SLIP, WHEEL THROWN |

| AG | 1 | CERAMIC, TOBACCO PIPE, IMPORTED, STEM, 4/64 INCHES |

| AH | 4 | GLASS, FRAGMENT, WINE BOTTLE |

| AI | 2 | GLASS, CLRLESS LEAD, FRAGMENT, CONTAINER |

| AJ | 7 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER |

| AK | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, OTHER MOLD DEC |

| AL | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, MOLD BLOWN, LETTERING/NUMB, R... |

| AM | 3 | GLASS, MANG SOLARIZED, FRAGMENT, CONTAINER |

| AN | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, OTHER MOLD DEC, YELLOW |

| AO | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, GREEN |

| AP | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, BROWN |

| AQ | 17 | GLASS, FRAGMENT, WINDOW GLASS |

| AR | 1 | SHELL, SHELL |

| AS | 1 | BONE, FAUNAL SPECIMEN |

| AT | 1 | OTHER INORGANIC, SLAG/CLINKER |

| AU | 1 | COARSE EARTHEN, BRICK, ALKALINE GLAZE |

| AV | 4 | IRON ALLOY, NAIL, LESS THAN 2 IN, WROUGHT/FORGED |

| AW | 8 | IRON ALLOY, NAIL, LESS THAN 2 IN, CUT |

| AX | 3 | IRON ALLOY, NAIL, 2 TO 4 IN, WIRE |

| AY | 1 | IRON ALLOY, NAIL, LESS THAN 2 IN, WIRE |

| AZ | 1 | IRON ALLOY, SCREW, LESS THAN 2 IN, MACHINE-MADE |

| BA | 10 | IRON ALLOY, NAIL, FRAGMENT |

| AA | 1 | REFINED EARTHEN, CREAMWARE, FRAGMENT |

| AB | 1 | REFINED EARTHEN, WHITEWARE, FRAGMENT |

| AC | 1 | STONEWARE, FULHAM SW, FRAGMENT, WHEEL THROWN |

| AD | 1 | CERAMIC, FRAGMENT, FLOWERPOT |

| AE | 3 | GLASS, FRAGMENT, WINE BOTTLE |

| AF | 1 | GLASS, CLRLESS NON-LD, FRAGMENT, CONTAINER, PRESSED |

| AG | 1 | GLASS, COLORED GLASS, FRAGMENT, BOTTLE, MOLD BLN/EMPONT, GREEN |

| AH | 1 | GLASS, COLORED GLASS, FRAGMENT, CONTAINER, GREEN |

| AI | 1 | GLASS, COLORED GLASS, FRAGMENT, OTHER MOLD DEC, WHITE |