Colonial Williamsburg Archaeological Reports

Archaeological Investigations of the Bracken Tenement Waterproofing Project

The Colonial Williamsburg Foundation

Department of Archaeological Research - RR1685

P.O. Box 1776

Williamsburg, VA 23187-1776

(757) 220-7330

February 2000

Management Summary

In February and March 1999, archaeologists from the Colonial Williamsburg's Department of Archaeological Research conducted an excavation around the Bracken Tenement (Block 2, Building 52), located on the south side of Francis Street between South England and Colonial Streets in Williamsburg, Virginia. In preparation for waterproofing the foundation of the building, trenches were excavated around the east half of the structure in the area that was to be directly impacted by the waterproofing activities. Despite the fact that in 1928 it was one of the first buildings restored by Colonial Williamsburg, the known history of this building is limited because of its location within James City County, whose records burned during the Civil War. Therefore, the archaeological record could provide much hitherto-unknown and needed information about the house and its former occupants.

The excavations consisted of one-meter-wide trenches around the building's east half, the side which encloses the original cellar. This included the area east of the front steps, all of the eastern side including the chimney, and east of the back porch on the south side. In addition, a two-meter-long trench was excavated on the western side of the front steps in an attempt to examine the change in the foundation where the building transitions from a full cellar to no cellar. The excavations were conducted following the natural stratigraphy until undisturbed subsoil was reached. Every feature, including those encountered in the subsoil, was documented and most were excavated. Furthermore, all soils, except those from known restoration or post-restoration contexts, were screened through one-quarter-inch mesh in order to collect any artifacts contained therein.

The excavations around the Bracken Tenement revealed cultural layers and features from its construction in the eighteenth century through its use as a Colonial Williamsburg house in the twentieth century. Because the ownership of the property is unclear during much of the house's history, the layers and the artifacts recovered cannot necessarily be associated with specific occupancies. However, they still did help to elucidate the house's evolution and use over time. The earliest information recovered concerned the construction of the house, which occurred most likely in the 1760s or early 1770s. The excavations also revealed the presence a previously-unknown bulkhead entrance under the current basement doorway. While the archaeological record confirmed that neither porch on the house was original, the excavations could provide little other information about earlier porches, probably due to the amount of modern disturbance and the limited excavation area. The occupation layers around the house revealed some interesting, if tentative, patterns concerning the deposition of artifacts in the eighteenth and early nineteenth centuries. In addition, a late eighteenth-century ditch, whose function is still unclear, was revealed on the east side of the building. Overall, the limited excavations provided valuable historical information about the Bracken Tenement but also proved that more archaeological research is necessary to understand the history of this property more completely.

iiTable of Contents

| Page | |

| Management Summary | i |

| List of Figures | v |

| Acknowledgments | vii |

| Chapter 1. Background | 1 |

| Historical Overview | 1 |

| Previous Archaeology | 5 |

| Chapter 2. Archaeology | 7 |

| Research Design/Methods | 7 |

| Results | 8 |

| Eighteenth Century | 8 |

| Nineteenth Century | 26 |

| Twentieth Century | 30 |

| Chapter 3. Conclusions and Recommendations | 33 |

| Conclusions | 33 |

| Suggested Further Research | 34 |

| References Cited | 37 |

| Appendices | |

| Appendix A. Context List | 39 |

| Appendix B. Artifact Inventory | 45 |

| Page | |

| Figure 1. Bracken Tenement as it appears on the Frenchman's Map | 1 |

| Figure 2. John Bracken's properties as indicated on the College Map | 2 |

| Figure 3. Locations of excavation trenches around the Bracken Tenement | 7 |

| Figure 4. Profile of north side builder's trench | 9 |

| Figure 5. Profile of bulkhead entrance under current basement entrance | 12 |

| Figure 6. Locations of extant eighteenth-century occupation layers around the Bracken Tenement | 13 |

| Figure 7. Plan view of ditch feature (M8) | 16 |

| Figure 8. Counterfeit Turlington bottle | 17 |

| Figure 9. Profile of ditch feature (M8) | 19 |

| Figure 10. Plan view of possible porch-related postholes | 20 |

| Figure 11. Profile of posthole 02KC-177 at the northeast corner of the Bracken Tenement | 23 |

Acknowledgments

Many thanks to the people whose cooperation allowed us to complete this project. Marley Brown, the Director of Archaeological Research, was supportive throughout. Staff archaeologist David Muraca provided invaluable guidance during the course of the excavation. The diligent field team included Carrie Alblinger, David Brown, Andrew Butts, Mark Kostro, Lily Richards, Katherine Schupp, and Lucie Vinciguerra. Donna Sawyers processed and inventoried all of the artifacts. Curator William Pittman and Assistant Curator Kelly Ladd also helped with the artifact interpretations. Heather Harvey produced all of the graphics. Architectural Historian Willie Graham and Architectural Conservator Tom Taylor provided insights into the architectural structure of the house.

viiiChapter 1.

Background

Historical Overview

Very little is known about the history of the Bracken Tenement, a building currently owned by the Colonial Williamsburg Foundation. Restored in 1928, it was one of the first historic buildings refurbished in the effort to recreate Virginia's colonial capital. Situated in Block 2 on the south side of Francis Street between the current South England and Colonial Streets, its location within the eighteenth-century boundaries of James City County is one of the main reasons few details of its history survive. During the Civil War, the James City County records were burned, and few historical documents pertaining to the structure remain. The building, which in the past has also been called the Bracken House and the Montague House, is now referred to as the Bracken Tenement because it is unclear whether the house's namesake, John Bracken, ever resided in it. Thus, any archaeological work around the Bracken Tenement should enlarge dramatically the body of historical knowledge concerning the structure.

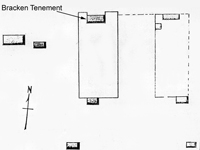

The Frenchman's Map, which most likely dates to 1782, depicts a building in the current location of the Bracken Tenement (Figure 1). The small rectangle on the map appears to represent a building of similar dimensions to the current structure, suggesting that the building was standing when the map was drawn. Consequently, the Bracken Tenement must have been constructed prior to the early 1780s. Besides showing the house, the Frenchman's Map also provides some details of the landscape around it. The map appears to depict an enclosed yard space, projecting north off of the two north corners, turning away from the house, and then south to enclose both side yards and a large back yard. Surprisingly absent is any depiction of the current Bracken Kitchen, reconstructed based on archaeology, just east of the southeast corner of the building. The kitchen may have been a later addition to the property, some time after the early 1780s.

Although the identity of the builder is unknown, the house takes its name from Reverend John Bracken, the rector of Bruton Parish Church and ninth president of the College of William & Mary. Bracken appears to have owned several lots between the current South England and Colonial Streets in the late eighteenth

Figure 1. Bracken Tenement as it appears on the Frenchman's Map.

2

century. Records suggest that Bracken was born in England and arrived in Williamsburg in the early 1770s. He became rector of Bruton Parish Church in 1773 and soon thereafter, in 1776, married into the influential Carter family. His new wife was Sally Burwell, the daughter of Carter Burwell of Carter's Grove plantation and the great-granddaughter of Robert "King" Carter. The couple had three children, John, Julia and Sarah, all born between 1779 and 1785 (Goodwin 1941: 354-57).

Figure 1. Bracken Tenement as it appears on the Frenchman's Map.

2

century. Records suggest that Bracken was born in England and arrived in Williamsburg in the early 1770s. He became rector of Bruton Parish Church in 1773 and soon thereafter, in 1776, married into the influential Carter family. His new wife was Sally Burwell, the daughter of Carter Burwell of Carter's Grove plantation and the great-granddaughter of Robert "King" Carter. The couple had three children, John, Julia and Sarah, all born between 1779 and 1785 (Goodwin 1941: 354-57).

According to the "College" map, which dates to the early 1790s, Bracken owned eight lots making up the entire block surrounded by the eighteenth-century

Figure 2. John Bracken's properties as indicated on the College Map.

3

England, Francis, Queen and Ireland Streets (Figure 2). Across Queen Street, his name also appears on Lots 241, the location of the Bracken Tenement, and 242 to the east. Previously, historical research had confused the main eight lots owned by Bracken with the eight lots further to the west on Francis Street where William Byrd's townhouse was located. As early as March 1777, Bracken was, in fact, residing in the townhouse belonging to the late William Byrd III as was advertised in the Virginia Gazette:

Figure 2. John Bracken's properties as indicated on the College Map.

3

England, Francis, Queen and Ireland Streets (Figure 2). Across Queen Street, his name also appears on Lots 241, the location of the Bracken Tenement, and 242 to the east. Previously, historical research had confused the main eight lots owned by Bracken with the eight lots further to the west on Francis Street where William Byrd's townhouse was located. As early as March 1777, Bracken was, in fact, residing in the townhouse belonging to the late William Byrd III as was advertised in the Virginia Gazette:

The executrix has also for sale a good brick house, situated in the city of Williamsburg with four rooms on each floor, lately occupied by the said William Byrd, esq; and at present by the reverend mr. Bracken. The dwelling-house has all convenient out houses, and several enclosed lots adjoining(Virginia Gazette, Purdie, ed., March 14, 1777).

In the past, it has been argued that Bracken bought the property from Byrd's widow when it was eventually sold in May 1778, as his name appears on the College Map for eight lots on the south side of Francis Street (Goodwin 1941: 358; Stephenson 1958:3-8). However, subsequent research has shown that Byrd's townhouse was in fact located at the west end of Francis Street and that the house and lots were sold to Samuel Griffin and not John Bracken (Townsend 1975; Richards 1999:1-2). It appears that Bracken simply rented Byrd's townhouse before purchasing his own eight lots further to the east on Francis Street several years later.

After the sale of Byrd's townhouse, Bracken and his family would have been required to move, but the location of their new residence remains a mystery. In the early 1780s, Bracken was teaching young boys out of his home (Stephenson 1958:6). He advertised in 1784 that he was willing to provide "the tuition of five or six boys, who may also live with him" (cited in Stephenson 1958:6-7). This would suggest that he was living in a relatively good size home to accommodate so many more children in addition to his own.

Even after the sale of Byrd's Francis Street townhouse, Bracken still seems to have had business dealings with Byrd's estate. A curious notation in the account books indicates the supposed payment of "rents" of £46.16.0 made by John Bracken to the estate in 1784 (cited in Stephenson 1958:7), six years after he moved out of the townhouse. While Byrd's estate does not appear to have possessed any other buildings in Williamsburg, it is clear that Bracken remained within the city of Williamsburg. In 1779, he advertised in the Virginia Gazette the sale of "the very Valuable LIBRARY and PHILOSOPHICAL APPARATUS of the Rev. John Camm at the house of the Rev. John Bracken in this city" (Virginia Gazette, Dixon and Nicholson, April 24, 1779). Interestingly, Byrd's estate records also indicate paying John Dixon to advertise a house in Williamsburg in 1786, paying Mathew Moody for tax on a Tenement for the year 1784 in 1787, and paying Robert Hyland "for crying1 a house in Wmsburg" in 1787 (cited in Stephenson 1962: 2). While it is possible that all of these notations were back payments and refer to the townhouse sold to Griffin in 1778, it is also possible that Byrd's estate 4 may have owned an unknown Williamsburg property that John Bracken could have rented after the sale of the Francis Street townhouse.

In 1786, Bracken and his family moved back to Francis Street when he purchased a brick house near the Market Square. In 1783, Philip Lightfoot had advertised the sale of "eight lots of land in the City of Williamsburg, whereon stands a large two story brick dwelling house, with four rooms on a floor; its situation esteemed one of the more pleasant in the City, lying on the back-street near to the market…" (Virginia Gazette or the American Advertiser, Hayes, ed., August 16, 1783). Parts of this brick house, which is currently referred to as the Lightfoot House, have been dated to the 1730s or 1740s based on their architectural style (Townsend 1975:1). Around 1750, the small house was renovated and turned into the impressive house that still stands today (Schlesinger 1979:6). The tax records from Williamsburg in 1786 registered the transaction in which Bracken purchased this property: "William Lightfoot to John Bracken———8 lots———£18." The tax records from the subsequent year indicate a tax of £16.16.- on six lots but it is also noted that "Mr. Bracken has only 6 lots but has been charged with Eight. H. Harwood" (cited in Stephenson 1958:7-8). This is a puzzling notation, as the College Map lists Bracken's name on all eight lots comprising the block in question. While the question of exactly how many lots Bracken owned remains unresolved, it is clear that he and his family were most likely residing in the Lightfoot House from at least 1786.

What remains a mystery in all of this is how and when Bracken acquired lots 241 and 242, both of which were separated from his main property by Queen Street in the eighteenth century. Unfortunately, nothing is known about the ownership of either of these lots prior to Bracken's name being associated with them on the College Map. The historical documents never attribute ten lots to Lightfoot, so it cannot necessarily be assumed that Bracken acquired these lots at the time he purchased his house, despite the confusion about the number of lots involved in the original sale. One thing that does seem clear is that the building now referred to as the Bracken Tenement was most likely standing prior to Bracken's purchase of lot 241. Assuming that Bracken and his family resided in a property owned by William Byrd's estate, as was suggested earlier, until the purchase of the Lightfoot House in 1786, then Bracken could not have built the small tenement as it appears on the Frenchman's Map of 1782.

Because Bracken already owned a large house on Francis Street, his usage of the additional properties is unclear. Besides lots 241 and 242, Bracken also acquired several other single lots along the south side of Francis Street at various times. These included the two lots east of 242, labeled "Js. Carter" and "Orrill" on the College Map (Stephenson 1965:1-2; Graham 1944:1-2). With ownership of these lots came several small houses, including not only the Bracken Tenement but also the Richard Crump House, the Lightfoot Tenement and possibly a house on the "Orrill" property.2 While Bracken may have been displaying his wealth and 5 influence by purchasing so much property, he most likely did use the houses, perhaps as rental properties.

Bracken began disposing of his Francis Street properties in the early nineteenth century. According to a letter written by Bracken, in 1802 he sold his block of eight lots, including his large brick house, to a Mrs. Dixon (cited in Stephenson 1958:10). As there is no mention in the city records of Dixon even owning the property, she probably held it only a short time before selling to Samuel Tyler (Stephenson 1958:10). The reason for Bracken selling the property is unknown. While he and his family could have briefly moved into one of their smaller houses, such as the Bracken Tenement, the records of the College of William & Mary indicated that he paid rent for the Brafferton House at the College in 1804 (cited in Goodwin 1941:359).

The details of the sales of his individual lots are, unfortunately, less clear than what is known of the sale of his main property. The Williamsburg Tax records indicate the sale of a lot to Elizabeth Carter in 1804. Different research reports argue that this transaction involved different lots: one argument says that the lot in question was 242, and may even have included 241, the location of the Bracken Tenement (Stephenson 1948:2); another says that the lot sold was the one east of 242, where the Richard Crump house has been reconstructed (Stephenson 1965:2). While this issue will most likely never be resolved, one detail that supports the lot in question as being 241 and possibly 242 is Tyler's insurance policy on the Lightfoot House, Bracken's former residence. In 1806, he describes Bracken's former home as being bounded on the east by "the Lott of Elizabeth Carter" (Mutual Insurance Policy #707, cited in Stephenson 1948:3).

Not much is known about any of the other nineteenth-century owners of the Bracken Tenement. After Elizabeth Carter, the next possible owner was George Southall, a Williamsburg lawyer. In 1842, a deed records him as the owner of approximately one acre of land, most likely including the Bracken Tenement. In 1854, Richard Hubbard owned one lot, which appears to have been the Bracken Tenement lot, according to the land tax records. In 1859, the Williamsburg land tax records note the transfer of this lot to Joseph Walthall. Victoria Lee, a resident of Williamsburg, recorded her knowledge of the town in 1861 and referred at the time to "the Walthall or Bracken House." Another resident, John Charles, described the Walthall house in 1861 as standing "on the south east corner of Queen Street, or Wales Alley," suggesting that the Walthall house was the Bracken Tenement and not the Lightfoot house, Bracken's main residence. The Walthall family most likely owned the house for some time because Anne Montague, the early twentieth-century owner of the Bracken Tenement, wrote in 1929 that many people in Williamsburg still remembered Mrs. Walthall (Stephenson 1948: 3-4).

Previous Archaeology

The yard around the Bracken Tenement on Block 2 has never been completely excavated. However, a map of the work conducted by James Knight, the architect charged with locating the foundations, indicates that the area around the Bracken Tenement was cross-trenched in May and June 1949. Unfortunately, no report 6 from this excavation has been located. Interestingly though, this means that the cross-trenching took place over twenty years after the building was restored. During the 1999 excavations, evidence of this cross-trenching was uncovered. Two sections of cross-trenches were found, both on the north side of the building, running northeast to southwest. Surprisingly, no cross-trenches were uncovered on either the east or the south sides of the building even though this area should have been investigated.

In 1949, archaeologists also uncovered portions of a kitchen foundation southeast of the Bracken Tenement and a building foundation to the east. Sections of the kitchen foundation included a chimney and part of the south wall and were used to reconstruct the kitchen which stands today. At the same time, most of the foundation of another Bracken property, the Bracken-Carter House (what is now called the Richard Crump House), were uncovered.

In 1983, archaeologists returned to the Bracken Tenement to observe the installation of a phone cable. A foot-wide trench running north-south was mechanically excavated between the south side of Francis Street and the Bracken Tenement in order to lay the cable. The trench jogged slightly to the west just before reaching the building's foundation at a point slightly east of the north porch. The stratigraphy for the trench was recorded and the few artifacts recovered inventoried, but archaeologists decided that nothing of archaeological importance had been disturbed (Samford 1983). A small section of this trench was uncovered during the 1999 excavations.

Chapter 2. Archaeology

Research Design/Methods

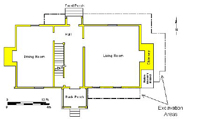

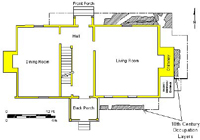

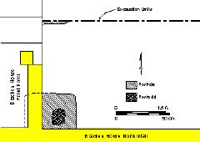

Archaeologists excavated trenches in the areas that were to be impacted most by the waterproofing activities around the Bracken Tenement (Figure 3). An almost-continuous one-meter-wide trench was dug encircling the exterior of the eastern half of the building, including the area around the chimney. A small break in the trench was left at the southeast corner of the building to allow entrance into the basement of the building and continued use of the brick pathway between the Bracken Tenement and Kitchen buildings. In addition, a two-meter-long, one-meter-wide trench was dug west of the front porch in order to examine the transition of the foundation from the side with a cellar to the side without a cellar.

Although there were modern disturbances to the excavation area, many intact layers and features from the eighteenth through twentieth centuries remained around the foundation. Parts of the original builder's trench and eighteenth-century occupation layers were uncovered on all three sides of the structure. Unfortunately, the only trench that contained no eighteenth-century remains was the one west of the front porch. This had been heavily disturbed by the installation of a

Figure 3. Locations of excavation trenches around the Bracken Tenement.

8

sewer line and revealed only traces of the nineteenth and twentieth centuries. In addition, this trench did not reveal the cellar transition, which appears to be under the front porch. Because much of the history of the house is unknown, linking the layers and features to specific occupations has proven to be all but impossible. However, the archaeology has still shed light on the use of the building since its construction and has provided much information that was previously unknown.

Figure 3. Locations of excavation trenches around the Bracken Tenement.

8

sewer line and revealed only traces of the nineteenth and twentieth centuries. In addition, this trench did not reveal the cellar transition, which appears to be under the front porch. Because much of the history of the house is unknown, linking the layers and features to specific occupations has proven to be all but impossible. However, the archaeology has still shed light on the use of the building since its construction and has provided much information that was previously unknown.

In order to understand the site and collect the archaeological information, the excavations were conducted in a controlled manner. The soil in each trench was excavated using trowels and shovels following natural stratigraphy. The different layers and features were recognized by changes in soil type, color, and texture. Each soil layer and feature encountered was assigned a unique context number by which it could be identified. In addition, a unique context number was assigned to each feature cut, a designation given to the event that led to the creation of a feature. While a cut is not a physical entity and will never have soil or artifacts, it is an important designation nonetheless, because a considerable amount of time may have passed between the creation and filling of that feature. All pre-Restoration soils were screened through one-quarter-inch mesh to recover any artifacts. During the excavation, detailed notes were recorded for every context in a palm-top computer. All of the records were downloaded from the palm-top into Re:Discovery, the computer database used by the Department of Archaeological Research.

All of the excavated artifacts were bagged by context and returned to the Archaeology Lab for processing—washing, inventorying, and bagging them for storage. The inventory process involved identifying each artifact, when possible, and describing its salient characteristics. These records were also entered into the Re:Discovery database. In the process of cataloging the artifacts, a terminus post quem (TPQ) date was assigned to each context based on the item with the most recent starting manufacture date. Because a group of artifacts cannot have been deposited before the most recent artifact was first manufactured, the TPQ dates are valuable when interpreting the formation of a site. After the artifact analysis was complete, the artifacts were rebagged and are currently stored at the Department of Archaeological Research Laboratory facilities.

Results

Eighteenth Century

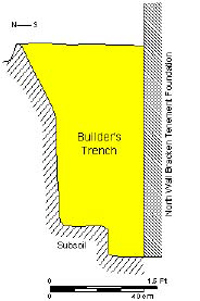

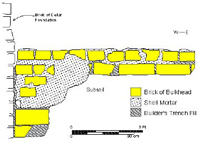

As the historical record pertaining to the Bracken Tenement is sparse, it was hoped that that archaeology could fill in some of the gaps, starting with a more specific date for the house's construction. A mostly intact builder's trench (master context M7), filled with compact olive yellow (Munsell color 2.5Y6/6) clay, was encountered on all three sides of the house around the cellar and chimney. This trench varied greatly in width, from 12 cm near its junction with the front porch to 72 cm off of the northeast corner. On the south side of the foundation, the builder's trench had suffered modern disturbances. A pipe trench, dug parallel to the foundation, had cut away the original edge of the builder's trench making it impossible to identify its original width in this area. Furthermore, a nineteenth-century feature 9 (master context M12) had disturbed the upper portion of the builder's trench between the pipe trench and the building.

During the course of the excavation, only two sections of the builder's trench could be excavated feasibly. The excavation of a builder's trench is a slow, difficult process not only because of the depth of the feature but also because of the small space provided the excavator between the edge of the feature and the foundation. Not only would removing all of the builder's trench fill have been difficult from an archaeological standpoint, it could also have been damaging to the foundation. Therefore, the decision was made to excavate a two-meter-long section (02KC-274) on the north side of the building and a one-meter-long section (02KC-288) on the south side. It was hoped that these two sections would provide enough information about the construction of the building so that further excavation would be unnecessary.

Even though the two sections of excavated builder's trench were essentially part of the same feature, they did exhibit some contrasts. For instance, the north section was 90 cm deep (Figure 4), while the south section was only 75 cm deep. This difference, however, was most likely due to a nineteenth-century disturbance (master context M12), which seems to have removed the top of the original trench in the back of the house, accounting for its shallower nature. When excavated, the trenches also exhibited slightly different profiles. The north trench tapered in slightly at the top before cutting straight down, allowing about 35 cm of space between the foundation and the trench wall almost to the bottom. The south trench, however, tapered much more gradually toward the foundation all the way down, reaching a width of only 15 cm some 30 cm above the base of the foundation. Another distinction between the two sections was related to the number of artifacts recovered in each. Part of this difference can be accounted for by the size disparity in the excavated sections and the partial disturbance to the builder's trench on the south side. However, the artifact ratio of over 8:1 favoring the north section seems unusual even with these factors. Therefore, it appears that the builder's trench on the north side of the house contained more artifacts than the trench on the south side, though the reason for this is unclear.

Despite the noted differences in the sections of the builder's trench excavated, the artifacts recovered can be analyzed together as they came from the same feature. These artifacts included tobacco pipe bowl fragments, wine bottle glass, window glass, fragments of animal bone, an oyster shell

Figure 4. Profile of north side builder's trench.

10

and fragments of iron, several of which were nails. In addition, three ceramic fragments were recovered: delftware, Fulham stoneware, and white salt glaze stoneware. While both delftware and Fulham were manufactured in both the 1600s and 1700s, white salt glaze stoneware was made only in the eighteenth century, helping to narrow down the date of construction for the house. The tiny white salt glaze stoneware fragment recovered was slightly blue, suggesting that the original decorative technique was either scratch/fill blue3 or Littler's blue.4 Therefore, the evidence from the builder's trench proves that the house could not have been constructed prior to 1744. In fact, given the time it would have taken for a new ceramic manufactured in England to reach the Colonies, it seems more likely that this evidence indicates that the house was not built at least until the 1750s.

Figure 4. Profile of north side builder's trench.

10

and fragments of iron, several of which were nails. In addition, three ceramic fragments were recovered: delftware, Fulham stoneware, and white salt glaze stoneware. While both delftware and Fulham were manufactured in both the 1600s and 1700s, white salt glaze stoneware was made only in the eighteenth century, helping to narrow down the date of construction for the house. The tiny white salt glaze stoneware fragment recovered was slightly blue, suggesting that the original decorative technique was either scratch/fill blue3 or Littler's blue.4 Therefore, the evidence from the builder's trench proves that the house could not have been constructed prior to 1744. In fact, given the time it would have taken for a new ceramic manufactured in England to reach the Colonies, it seems more likely that this evidence indicates that the house was not built at least until the 1750s.

Other construction-related evidence uncovered included two scaffolding holes along the eastern chimney and another possible one on the south side of the house. The two holes east of the chimney both cut the builder's trench and are sealed by the earliest occupation layer along the eastern side of the building. One hole (whose fill is context 02KC-214 and cut was 02KC-215, hereafter 02KC-214/215) was located 20 cm south of the northeast corner of the chimney and little less than 10 cm from the chimney base. Measuring 29 by 24 cm, this hole was almost rectangular and had an irregular base, with the end closer to the chimney being slightly deeper and reaching its maximum depth at 17 cm. It contained mottled olive brown (2.5Y5/6) sandy clay loam and revealed no artifacts except for a few small brick chips. A second scaffolding hole (02KC-212/213) was located about 10 cm north of the southwest corner of the chimney and a little less than 10 cm from the chimney base. Slightly smaller than the first hole, it measured 19 by 17 cm and was 11 cm deep. It was filled with light olive brown (2.5Y5/4) clay loam and it too contained no artifacts except for a few small brick chips. A third possible scaffolding hole was excavated on the south side of the building, near the back porch. The shallow square feature (02KC-272/273) measured approximately 15 cm on each side and was 6 cm deep. The fill was an olive brown clay loam and contained only wine bottle glass, animal bone and a nail fragment. Although this feature cut the builder's trench, it was sealed by the nineteenth-century "repair" feature (master context M12), meaning it could have been dug any time from just after the house was constructed to well into the nineteenth century. Because of the lack of stratigraphic relationships, it is only possible, therefore, to speculate that this may have been a scaffolding hole.

In addition to the builder's trench and the scaffolding holes, several other features cut subsoil and were sealed by the earliest occupation layers, a combination which may indicate that they were construction-related. On the northern side of the building, evidence existed for a relatively large pit (02KC-208/209) having been dug into the subsoil. This pit was backfilled with redeposited olive yellow (2.5Y6/6) clay subsoil and mounded over. The upper portion (02KC-207) raised above the subsoil level was at first treated as a separate feature until the sidewall profile revealed that it was a mounded pit. The exact size of this pit is unclear 11 because it extended out of the excavation area but it is relatively large with a length of 114 cm, a width greater than 40 cm, and a depth of 60 cm. Because of the depth and sterility of the pit, only half of it within the excavation area was removed. The fill of the two contexts contained a few artifacts, all of which were architectural in nature, including window glass, copper alloy sheet metal, brick fragments, and wrought nail fragments. While the exact purpose of this pit is unclear, the evidence suggests that this feature was construction-related and was filled in prior to the occupation of the house.

The excavation also uncovered evidence of an early bulkhead entrance (02KC-203) on the east side of the house, under the current basement doorway. Previously, it had been known that the current basement entrance was not original, though it had been added prior to Colonial Williamsburg acquiring the house (Kocher and Dearstyne 1951:7). The presence of an earlier bulkhead entrance should not be surprising given the fact that the interior stairs to the basement were most likely added when the basement was enlarged between 1890 and 1900 (Shurtleff 1930:15). Therefore, prior to this time, the only access to the cellar would have to have been through an exterior entrance.

The presence of the earlier bulkhead entrance first came to light while excavating on the east side of the building. The excavation trench originally had ended at the north edge of the current basement entrance to allow continued access into the cellar. However, when parts of two bricks were revealed in the southwest corner of the trench, a one-meter-long, half-meter-wide extension was dug on the south end. Under the layers of fill from constructing the current basement entrance and from backfilling the bulkhead entrance (master context M135), several more bricks were revealed. Bricks were present at the two corners of the basement entrance but had been disrupted in the middle by a more modern feature (02KC-236/237). Unfortunately, the installation of the current basement entrance had covered most of the bricks with concrete so it was clear that much of the evidence pertaining to the bulkhead had been destroyed or was, at the very least, inaccessible. A small part of the original builder's trench (02KC-238/239), however, was present around the visible bricks. It contained olive brown (2.5Y4/4) sandy loam, which differed greatly from the clay fill of the builder's trench around the rest of the structure, and unfortunately produced no artifacts.

During the course of the waterproofing, more of the bulkhead was inadvertently revealed. When the waterproofing trench along the south side of the building was dug, seven courses of brick became visible in the profile under the current basement entrance (Figure 5). The archaeological excavations had stopped previously to the east because of the presence of considerable modern disturbance, ruling out the possibility of much intact stratigraphy in this area. This view of the brick in the profile confirmed its interpretation as a bulkhead. The upper two courses spanned the 115 cm base of the current basement entrance and the successive

12

Figure 5. Profile of bulkhead entrance under current basement entrance.

rows underneath diminished in length, with the lowest being only 20 cm. The bricks were reddish-orange in color and cemented with shell mortar, implying that they were eighteenth-century.

Figure 5. Profile of bulkhead entrance under current basement entrance.

rows underneath diminished in length, with the lowest being only 20 cm. The bricks were reddish-orange in color and cemented with shell mortar, implying that they were eighteenth-century.

Determining whether this was the original bulkhead entrance was difficult because of the rather limited view allowed by the presence of the current basement entrance. One possible clue that might indicate that this bulkhead was a replacement for an earlier one is that the bricks from the bulkhead were not visibly tied into the foundation. That is to say, the bricks from the foundation and the bricks from the bulkhead both had vertical edges that merely abutted each other rather than overlapping. While it is possible that the bricks were attached on the interior, this could not be proven without removing the current basement entrance. However, the bricks and the mortar, as noted earlier, appeared eighteenth-century in date. Thus, if the bulkhead was not original, then the first one was quite short-lived.

In addition to construction-related information, the excavations revealed evidence of the earliest occupations (Figure 6). The earliest occupation layer left only traces on the north side of the building. The thin deposit of light olive brown (2.5Y5/4) fine silty loam (master context M6) was only on top of the builder's trench where the eaves could have protected it. It is unclear whether this soil just covered the builder's trench or originally extended out away from the house. The north edge of the fill tapered out gradually in such a fashion as to suggest that it might have eroded slightly. The artifacts recovered included fragments of creamware, red-bodied slipware, unidentified coarseware, Westerwald, press-molded white salt glaze stoneware and Chinese porcelain, fragments of leaded table glass and

13

Figure 6. Locations of extant eighteenth-century occupation layers (context 183) around the Bracken Tenement

window glass, fragments of animal bone, an oyster shell, and architectural debris. The TPQ was 1762 based on the presence of creamware.

Figure 6. Locations of extant eighteenth-century occupation layers (context 183) around the Bracken Tenement

window glass, fragments of animal bone, an oyster shell, and architectural debris. The TPQ was 1762 based on the presence of creamware.

The next occupation layer (master context M5) on the north side of the house was also eighteenth-century. It was olive brown (2.5Y4/4) sandy loam. This soil, which averaged about 10 cm deep, was present across much of the north side of the house, although it had been cut away in many places by more modern intrusions. This layer contained domestic refuse, which was more concentrated closer to the front porch. The ceramics represented include creamware, pearlware, red-bodied slipware, unidentified coarseware, white salt glaze stoneware, Westerwald, Fulham stoneware, and Chinese porcelain. Other artifacts found in this layer included a tobacco pipe bowl, table glass, wine bottle glass, pharmaceutical bottle glass, window glass, animal bone fragments, a copper alloy upholstery tack, unidentified iron hardware, and nails. While the TPQ of the layer is 1775 based on the single sherd of pearlware recovered, creamware definitely predominated suggesting that this layer does not represent an occupation stretching much into the 1780s, the time by which pearlware had become quite popular. Thus, it seems likely that the layers of M5 and M6 were associated with the original tenant or tenants, who probably occupied the house prior to John Bracken's purchase of the property.

The olive brown (2.5Y4/3) sandy loam layer (02KC-168), located on the east side of the modern fence projecting off of the house's north corner, was most 14 likely from the same depositional period as M5. The artifacts included Fulham stoneware, aqua pharmaceutical glass, wine bottle glass, window glass, animal bone fragments, slag, and nail fragments. While a fragment of whiteware was recovered from 02KC-168, it appears that this was intrusive. Excavators had had trouble distinguishing between 02KC-168 and 02KC-165, the nineteenth-century layer on top of it, and the single piece of whiteware seems out of place in a context whose other most recent artifact is creamware. Because of modern features, the eighteenth-century layers on either side of the current fence were not contiguous, making it difficult to determine whether they were, in fact, equivalent. Measuring 11 cm, 02KC-168 was a thicker deposit than others in M5, but this was probably related to erosion and the slope of the yard in this area. The soils looked quite similar except for a slight difference in Munsell color, and therefore were most likely related.

Cut into layer M5 was evidence of an early dripline (master context M4) created by water running off of the roof. The location of this dripline feature suggests that the roofline has not changed much since the house was constructed, as the dripline was in much the same place and took the same form as the more recent ones seen higher up stratigraphically. Although the soils in the dripline and the surrounding layer were quite similar, they were removed separately because of the different actions involved in the creation of each. The dripline began roughly 40 to 50 cm from the base of the foundation and varied from 30 to 42 cm in width. While this may seem wide for a dripline, it was clear based on the sheer number of artifacts concentrated in this area that there was a different force acting on this soil than on the surrounding layer. The most likely explanation is that the ground became softer and slightly eroded because of the dripline action. As the artifacts concentrated naturally in the spongy ground, the moisture spread outward into the more absorbent soil around them, slowly widening the artifact concentration with time. Therefore, it seemed important to examine these artifacts separately from those recovered from the surrounding layer as the dripline action could very well have lasted longer than the occupation with which the layer was associated. The artifacts recovered from the dripline spanned a much longer time range than those from the surrounding eighteenth-century layer (master context M5) but were also more numerous. The ceramics included creamware, pearlware, a single fragment of whiteware, dipped white salt glaze, and Chinese porcelain. Other artifacts found were leaded table glass, wine bottle glass, mirror glass, over 100 fragments of window glass, a copper alloy button, iron hardware and many nail fragments. Because of the extended action of the dripline, it is virtually impossible to understand the context in which these artifacts should be understood in relation to specific occupancies.

In contrast to the northern side of the house, the eighteenth-century occupation layers on both the eastern and southern sides were quite patchy. On the southern side, a modern pipe trench ran down the center of the excavation trench, parallel to the foundation, approximately where the dripline would have been. A nineteenth-century disturbance (master context M12) had disrupted the soil between the pipe trench and foundation all the way down to the builder's trench. Thus, the only remnant of the eighteenth-century occupation layer was a 37-cm- 15 wide strip of dark olive brown (2.5Y3/3) sandy loam with white patches (02KC-262) running the length of the trench. This deposit was almost twice as thick as the earliest occupation layer in the front, extending up to 20 cm in depth in places. The artifacts included creamware, pearlware, colono ware, tobacco pipe fragments, animal bone, oyster shell, window glass, unidentified hardware, and nail fragments. The TPQ of the layer was 1787 based on the two fragments of pearlware, which exhibits a blue printed design under the glaze. This stratum may represent a longer depositional period than the occupation layers on the north side (master contexts M5 and M6) as indicated by the relative thickness and more recent TPQ. Therefore, 02KC-262 may be associated not only with the earliest occupation of the house but also with John Bracken's ownership.

The only other intact eighteenth-century intact layer uncovered around the Bracken Tenement ran along the eastern side of the east chimney. This mottled olive brown (2.5Y4/4) clay loam (02KC-183) was 8 cm deep and sat on top of the builder's trench for the chimney. The only ceramics found in this layer were delftware and colono ware, both of which are undateable, but this layer sealed a feature (02KC-205) containing creamware, which means it could have been deposited no earlier than 1762. Other artifacts unearthed included a tobacco pipe bowl fragment, leaded table glass, pharmaceutical bottle glass, wine bottle glass, animal bone, lead casting waste, coal and nails fragments. The recovery of so few ceramics is most likely related to its location away from both main doors of the house. Instead, the artifacts may be remnants of activities that occurred in the east yard or in the cellar. While these artifacts could be related to the nearby kitchen, this seems unlikely on account of the paucity of ceramics. Furthermore, the kitchen is absent from the Frenchman's Map, suggesting that it was not standing when the layer was deposited. Whether the artifacts are related to activities in the kitchen or the tenement, the presence of coal within the layer is important to note. An unusual ditch feature, just to the north of this occupation layer, contained considerable amounts of coal. As this was the only feature on the site to contain so much coal, the occupation layer was probably deposited during the formation and use of the ditch feature.

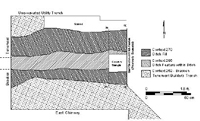

The ditch feature (master context M8) was curious in that it projected east from the east side of the foundation, running along the north edge of the chimney and out into the yard (Figure 7). While the feature clearly continued outside of the excavated area, the visible portion extended the 231 cm of the excavation trench and spanned 115 cm, from the chimney on its south to the unexcavated utility trench on its north. The ditch turned out to be 42 cm deep and contained several different fill layers. The fill within the feature contained quite a few artifacts, especially in the upper layers, and exhibited considerable amounts of coal throughout.

One of the most interesting aspects of this ditch feature was its interface with the foundation of the house. It adjoined a section of brick wall that turned out to be quite deteriorated, with many of the bricks having been removed or crumbled from the foundation. When the feature was excavated, the brickwork became solid again only four cm above the bottom of the ditch. While the ditch and the problematic section of the foundation are clearly related, which one resulted in the other was not so obvious. That is to say, the installation of the ditch may have

16

Figure 7. Plan view of ditch feature (M8).

caused the decay in the foundation or the ditch was excavated in an attempt to alleviate the problems in the bricks. Either way, the deteriorated bricks have been a problem for quite some time and may be one of the reasons that the foundation requires waterproofing today.

Figure 7. Plan view of ditch feature (M8).

caused the decay in the foundation or the ditch was excavated in an attempt to alleviate the problems in the bricks. Either way, the deteriorated bricks have been a problem for quite some time and may be one of the reasons that the foundation requires waterproofing today.

Over the years, the ditch feature has suffered from some modern intrusions. A utility trench ran along the north side, which appeared to have narrowed slightly the width of the upper layer. However, the impact of this feature on the trench appears minimal because the ditch profile under the uppermost layer of fill was intact. Unfortunately, two rather deep utility trenches had cut across the feature, disturbing approximately 35 cm of the ditch at its east end within the excavation area. It is clear, however, that the ditch once continued through this area and out into the yard, as faint traces of it were visible at the bottom of the excavated utility trenches.

The uppermost layer of soil in the feature (02KC-269) spread across the top of the whole ditch, all the way to the north wall of the chimney on the south and to the utility trench on the north, spanning 115 cm. The original width of the fill layer was most likely not much greater than this as the shape of the ditch underneath was complete. Besides covering the top of the ditch, the soil also reached 25 cm into the deteriorated section of the foundation. The soil deposit, which was approximately 16 cm deep, was characterized as yellowish brown (10YR5/8) sandy clay loam and contained brick, charcoal, coal and shell inclusions, including 52 whole oyster shells. With over 300 artifacts, this soil contained more and a larger variety of artifacts than almost any other context excavated. The ceramics found included delftware, creamware, pearlware, red-bodied slipware, black-glazed redware, black basalt, and Chinese porcelain. The TPQ for the upper layer of the ditch fill was 1790 based on the fragment of annular pearlware recovered. 17 Most of the other artifacts in this context were fairly typical domestic items of the eighteenth century, including tobacco pipe fragments, leaded table glass, pharmaceutical bottle glass, wine bottle glass, window glass, animal bone fragments, nail fragments and an assortment of metal hardware, including a copper alloy upholstery tack and a window lead.

One of the most unusual items recovered during the excavation was a fragment of a leaded glass Turlington-type patent medicine bottle (Figure 8), which came from this uppermost layer of ditch fill. Turlington's Balsam of Life was a 27-ingredient elixir, patented by Robert Turlington in 1744. Originally sold in cello-shaped bottles, the medicine became fashionable among the populace and an easy source of income for counterfeiters, who would refill the recognizable bottles with their own mixtures. As a result, Turlington changed the bottle shape in 1754 to be more angular in order to discourage counterfeiting. Turlington's efforts do not seem to have worked and counterfeit bottles, identifiable quite often by mistakes in their text, continued to be made. The fragment recovered from the ditch fill appears to be just such an example of an eighteenth-century counterfeit. Because the extant portion of the bottle only consists of the base and lower sections of the sides, the full text is unavailable for examination. However, the bottle exhibits the molded letters "IAN…" which on a real Turlington bottle should read "JAN#x2026;" for "JANUY" in the date. Furthermore, the use of clear leaded glass indicates that it is an English fake rather than an American one, which would have been made of green to blue-green non-leaded glass (William Pittman, personal communication, 1999).

Under 02KC-269, the next lower layer of ditch fill (02KC-270) was much narrower in width, measuring only 62 cm across. Measuring 11 cm deep, the yellowish brown (10YR5/8) sandy clay loam, though quite similar to the upper layer above exhibited some silty and clayey patches. This soil also contained inclusions of brick, charcoal, coal and shell. The fill also contained a variety of eighteenth-century domestic artifacts though a little less than half of the number recovered from the above layer. The artifacts included creamware, black-glazed redware, Fulham stoneware, Chinese porcelain, tobacco pipe stem fragments, wine bottle glass, window glass, animal bone, oyster shells, a window lead, unidentified iron hardware and nail fragments. The presence of creamware provided a TPQ of 1762. However, based on the TPQs of lower layers in the ditch, this fill could have been deposited no earlier than 1775.

Figure 8. Counterfeit Turlington bottle.

Figure 8. Counterfeit Turlington bottle.

At the interface of the upper two layers of fill, 02KC-269 and 02KC-270, there was a faint linear stain (02KC-296/297) that ran down the center of the ditch. It turned out to be a shallow rounded groove measuring a little over 20 cm across and only 12 cm deep. Interestingly, this linear stain was aligned with the deepest recess in the bricks of the foundation and was similar in width to that recess, details that suggest a probable relationship. The edges of the groove in the soil were difficult to determine as the feature fill was only slightly darker than the surrounding layer of ditch fill. Unfortunately, the feature contained no artifacts. Though this linear stain probably existed in both halves of the feature, it was not nearly as evident in the ditch's east half, the side removed first, and was missed during the excavation process. As a result, the continuation of this stain in the east half appears to have been inadvertently removed along with the surrounding fill layer (02KC-270). While documenting this feature of the east half of the ditch would have been advantageous, it does not appear to have compromised much 02KC-270 because of the size of the feature and the lack of artifacts recovered from the excavated portion.

The next lower fill in the trench (02KC-271) comprised most of the remaining ditch fill. The compact light yellowish brown (2.5Y6/4) silty sand covered much of the bottom of the trench. The upper two fill layers contrasted greatly with this soil, which was much sandier and lighter in color. In addition to the brick, coal, charcoal, and shell inclusions common to all of the fills of the ditch, this layer also included fragments of shell mortar, probably from the crumbling section of the foundation. The majority of artifacts recovered were fragments of animal bone, window glass and oyster shells. Other artifacts included creamware, black-glazed redware, pearlware, a tobacco pipe stem fragment, non-leaded table glass, and nail fragments. The presence of the single sherd of blue-painted pearlware provided a TPQ of 1775.

The lowest two deposits, which were quite thin and sporadic, were most likely related to silting episodes that occurred while the ditch stood open. A thin deposit of brownish yellow (10YR6/8) silt (02KC-279) underlay the gray compact silty sand, and partially lined the sides of the ditch. The few artifacts recovered from this soil were a fragment of animal bone and an oyster shell, but it did contain small inclusions of brick, mortar, coal and charcoal. Interestingly, 02KC-279 became increasingly shallow the closer the ditch became to the foundation of the house and was virtually nonexistent within 30 cm of the foundation.

The earliest deposit of soil (02KC-290) within the ditch contrasted starkly with all of the other fills in that it was black (10YR2/1) silt running across the deepest part of the trench. The dark color was most likely caused by the presence of small fragments of coal and charcoal within the fill. The artifacts present included Chinese porcelain, table glass, wine bottle glass, window glass, animal bone fragments, and oyster shells, in addition to brick and mortar debris. Unfortunately, none of these artifacts provided a TPQ to indicate when the siltation occurred or to provide an idea of when the ditch was originally dug.

Overall, several observations can be made to further the understanding of this complex feature (Figure 9). First of all, based on the thin deposits of silt at the bottom, the ditch appears to have stood open for at least a short amount of time

19

Figure 9. Profile of ditch feature (M8).

Figure 9. Profile of ditch feature (M8).

before the soil was replaced. When the ditch stood open, the bottom was relatively level: the difference in height between the point next to the foundation and one 165 cm away was only 6 cm. This means that the slope, assuming it was constant, was less than 4%. When it was backfilled, two separate fills, light yellowish brown silty sand and yellowish brown sandy clay loam, were used. However, how much time, if any, elapsed between the deposition of these two fills is unclear. The filling process could have begun no earlier than 1775 and been completed no earlier than 1790. However, the differences in these dates in no way prove that the backfilling was not a single event sometime after 1790. Another important aspect of the ditch is the linear stain that ran down its length between the two deposits of yellowish brown sandy clay loam. One possible explanation for this groove is that it once held a conduit of some sort, such as a pipe, that entered the house through the recess in the foundation. While this interpretation cannot be ruled out, two characteristics of the ditch make it seem unlikely. First of all, the lack of slope within the ditch appears unconducive to movement within the channel. Secondly, why would the creator of the ditch have put so much extra effort into digging the ditch much deeper than the level of the channel? While this explanation is only hypothetical, the similarity but distinction between the soils around it might indicate that the fill above the channel was taken out and then replaced after the removal of the conduit.

Because such a small section of this feature has been excavated, many of the details of its interpretation can only be considered conjectural. One thing that is certain is that the ditch was used for trash deposition, although this was most likely 20 only a secondary usage. The complex form of the ditch implies that it was more than a trash pit, but once opened, it would have provided an ideal location for the disposal of unwanted materials. The presence of so many artifacts within this feature might also suggest a concerted effort by the house's late eighteenth-century occupants to place their trash in this ditch. This would have kept the yard space around the building neater and might explain why the excavated occupation layers from this time appear relatively clean.

While the ditch was clearly used as a trash pit, determining its main function can only be hypothetical. However, two key characteristics of the fill may provide some insights into the original intent of the person who installed the ditch. One of the attributes is the presence of so much coal in the fill, suggesting that the black ore was being burned nearby, perhaps in conjunction with heating the house or an industrial activity. The other key aspect of this feature that may relate to its function is the linear stain found within the fill. If this channel indicated the former location of a conduit, then the ditch was related to getting some substance in or out of the house. Unfortunately, the function of this ditch will have to remain speculative until further research is conducted.

In addition to the ditch, several other several eighteenth-century features, many of which were postholes, came to light during the course of the excavation. Because the excavation design was limited to one-meter-wide trenches, understanding postholes can be quite difficult since the full picture was often lacking. Therefore, it is only possible to provide a listing of any postholes uncovered, including their TPQs and possible interpretations.

The only possible evidence uncovered for an early porch on the front of the house was in the form of two postholes along the east side of the current porch (Figure 10). The front porch is clearly not original to the house and is possibly even a second or third incarnation on the house in the twentieth century alone. The two postholes found were most likely from an earlier porch, possibly an eighteenth-century one. Surprisingly, neither of these postholes had a counterpart on the porch's western side, but they could have been destroyed by more recent

Figure 10. Plan view of possible porch-related postholes.

21

intrusions. The amount of modern disturbance around the current porch, especially on the western side, may prevent a complete understanding of the form of the original porch.

Figure 10. Plan view of possible porch-related postholes.

21

intrusions. The amount of modern disturbance around the current porch, especially on the western side, may prevent a complete understanding of the form of the original porch.

The most complete of the two porch-related postholes had a medium sized mold (02KC-217) and a relatively large posthole (02KC-218/219), part of which goes under the extant porch. The mold, which measured approximately 14 cm in diameter, contained light olive brown (2.5Y5/4) silt loam but no artifacts. The posthole itself was characterized by brownish yellow (10YR6/6) sandy clay fill and measured 48 by 35 cm, which included the portion under the concrete of the modern porch. The only artifacts recovered from the posthole fill were two fragments of iron. Unfortunately, the stratigraphy was only slightly more helpful than the artifacts in determining a date for this posthole. A archaeological cross-trench (02KC-117/118) had removed the upper portion of the posthole. Consequently, the post had been removed prior to the cross-trenching in 1949. The posthole fill cut layer 02KC-204, which appeared to be part of M5, the eighteenth-century occupation layer from the 1760s and early 1770s. Therefore, this posthole could not have been from the original porch for the house, but rather a subsequent porch constructed between the late eighteenth century and the early twentieth century.

The sidewall profile showed the presence of another probable posthole (02KC-302/303), just north of the excavation area on the eastern side of the current porch. While its location precluded its excavation, it cannot be original to the construction of the house as it was more recent than at least one occupation layer. The posthole cut clay fill (02KC-198) which was on top of 02KC-204, part of the occupation layer dating to the third quarter of the eighteenth century. The olive yellow (2.5Y6/6) clay deposit ran along the eastern side of the north porch and contained window glass, bone fragments, and nail fragments, none of which provide a TPQ. As a result, postholes 02KC-218 and 02KC-302 could have been from the same porch. Posthole 02KC-302 was sealed by several bricks (02KC-123) also visible only in the sidewall profile. The three bricks were two courses high and were most likely from yet another porch incarnation. The bricks appeared to have concrete in between them, suggesting that they were relatively recent. However, further archaeological work would be necessary to rule out the possibility that the concrete was repair-related.

Another posthole uncovered during the excavation (02KC-264/265, postmold 02KC-263), was located slightly west and north of the northeast corner of the building. The postmold was relatively large, measuring 22 by 16 cm. The mold was filled with olive brown (2.5Y4/3) fine sandy loam and contained only a single piece of coal. The posthole was not exposed in its entirety because of its location on the edge of the excavation area. The extant portion was rectangular with rounded ends and measured 60 cm in length and more than 28 cm in width. The fill consisted of light yellowish brown (2.5Y6/4) sandy loam containing inclusions of coal and brick. The artifacts recovered from the posthole fill included several varieties of ceramics, (one of which was creamware which provided the TPQ of 1762), glass, animal bone, an oyster shell and a piece of unidentified iron hardware. Stratigraphically, it was one of the earliest postholes as it cut subsoil and was cut by several other features, which also appeared at the subsoil level.

22While these features were not sealed by an early occupation layer, the clay deposit (02KC-139) on top of them did appear to be eighteenth-century in date. Although the early nature of this posthole might indicate that it was scaffolding-related, the presence of coal within the posthole fill would imply it was dug while the house was occupied, and not before. Therefore, the most plausible interpretation is that the post was fence-related but the location of the rest of the fence is unknown.

Part of posthole 02KC-264 had been cut by a more recent posthole (02KC-260/261), possibly its replacement. Posthole 02KC-260 was filled with olive brown (2.5Y4/4) sandy clay loam. It appears to have been originally rectangular, measuring 36 by 21 cm, and was located just south of 02KC-264 so that the two postholes overlapped by approximately 10 cm. Posthole 02KC-260 contained only a few artifacts, including creamware, green pharmaceutical glass, window glass, and a wrought nail fragment. Thus the posthole could not have been put in prior to 1762. No evidence of a postmold for this feature ever emerged because an even more recent feature, 02KC-188, had cut into its center, probably obliterating any traces of a mold.

Context 02KC-188, which appeared unrelated to either of the postholes, was most likely a planting hole as indicated by irregular profile. Round in shape, it contained light olive brown (2.5Y5/4) silty clay loam with small brick chips. The artifacts recovered were creamware, Chinese porcelain, leaded table glass, wine bottle glass, window glass, and animal bone. This hole, too, had a TPQ of 1762, though it was clearly more recent than the hole it cut.

Approximately 14 cm to the east of posthole 02KC-264 was another possible posthole (02KC-199/200), which also extended out of the excavation area. The extant portion measured 27 by 24 cm and was 25 cm at its deepest point. The fill was light olive brown (2.5Y5/4) sandy clay loam and showed no evidence of a mold, which could have been outside of the excavation area. The profile shape was fairly straight-sided, with the edges tapering in slightly toward the bottom. The feature contained a fragment of white salt glaze stoneware and a fragment of creamware, providing the TPQ of 1762.

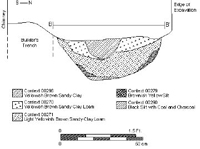

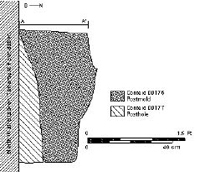

On the north side of the northeast corner of the house, the archaeological record revealed the presence of another eighteenth-century posthole (02KC-177/178) (Figure 11). The Frenchman's Map appears to depict an enclosure around the Bracken Tenement projecting north from this corner of the building. Posthole 02KC-177 is the earliest surviving posthole in this location, clearly a popular one for posts as several other more recent postholes had to be removed to expose the remains of this one. The mold fill (02KC-176) was characterized as olive brown (2.5Y4/4) silty loam and contained seventy artifacts, a considerable number for a postmold. The artifacts recovered included an assortment of ceramic and glass fragments, animal bone, an oyster shell, coal and nails. The TPQ of the mold was 1800 based on a fragment of bone china. The profile of the mold, which was wider at the top and narrow at the base, indicated that someone had to rotate and jiggle the post in order to remove it from the ground, sometime in the nineteenth century.

23

Figure 11. Profile of posthole 02KC-177 at the northeast corner of the Bracken Tenement.

Figure 11. Profile of posthole 02KC-177 at the northeast corner of the Bracken Tenement.

Because of the movement of the post and more recent intrusions, only small sections of the light olive brown (2.5Y5/4) sandy clay loam posthole fill remained. As compared to the mold, few artifacts were recovered. None of the posthole artifacts, such as fragments of leaded table glass, window glass, animal bone, iron hardware, and nails, provided a TPQ that would indicate the fence's construction date. Unfortunately, the intrusions around the posthole removed much of the stratigraphy so the only known relationship was that the posthole cut the builder's trench of the house. However, the post was most likely not original to the construction of the house but could be related to the enclosure shown on the Frenchman's Map. Assuming a wooden post lasts on average 20-30 years before succumbing to decay, then a post removed sometime after 1800 was put in no earlier than 1770-1780. The shape of the mold, however, indicated that the post was relatively intact when removed, and therefore, more likely closer to 20 years old than 30. All in all, the presence of this posthole supports the interpretation of an enclosure projecting off the northeast corner as indicated on the Frenchman's Map.

In addition to the postholes, several other eighteenth-century features were uncovered on the north side during the course of the excavation. One example, a shallow deposit of light olive brown (2.5Y5/6) clay (02KC-139) was located north of the dripline adjacent to the house's northeast corner. The clay contained delftware, creamware, pearlware, a tobacco pipe stem, window glass, animal bone, flint debitage, and nail fragments, an assemblage with a TPQ of 1775. Without knowing its full extent outside of the excavation area and its stratigraphic relationship to the eighteenth-century occupation layer, the cause of this deposit will remain unclear.

Another unidentified eighteenth-century feature (02KC-205/206) was located between two modern postholes along the north wall of the excavation area just east of the northeast corner of the building. The dimensions of the extant 24 portion were 25 by 22 cm and 28 cm deep. Despite being distorted by modern features, the small hole was clearly once round in shape. The fill was light olive brown (2.5Y5/4) sandy clay loam and contained forty-one artifacts, with a TPQ of 1762, including creamware, coarseware, stoneware, leaded table glass, wine bottle glass, window glass, animal bone, an iron buckle and nail fragments. The irregularity of the profile and the lack of a mold suggest that it was most likely a planting hole, rather than a posthole. Context 02KC-205 also cut an unidentified linear feature (02KC-210/211), running north-south. The early feature, which continued out of the excavation area, measured 65 by 24 cm and was only 4 cm deep. The olive brown (2.5Y4/4) sandy clay loam fill contained a single nail fragment.

On the east side of the house, an unidentified eighteenth-century feature was present. The feature was a rounded rectangular hole (02KC-192/193), measuring 43 cm by 36 cm, and cutting the builder's trench on the east side of the chimney. The hole was filled with olive brown (2.5Y4/4) clay loam and contained creamware, North Midlands slipware, an unidentified underfired stoneware, chinese porcelain, leaded table glass, wine bottle glass, including a hand-tooled finish, pharmaceutical bottle glass, window glass, animal bone fragments, oyster shells, unidentified iron hardware, and a nail fragment. The probable bush hole could not have been backfilled prior to 1762, established by the presence of creamware, and was sealed by the earliest occupation layer on this side of the structure (02KC-183).

On the south side of the house, a few eighteenth-century features survived. A small stake hole (02KC-277/278) was uncovered under the earliest eighteenth-century occupation layer. Filled with dark yellowish brown (10YR3/4) sandy loam, it contained no artifacts. The stake hole also cut an unidentified feature (02KC-284/285). This pit, the extant portion of which measured 67 by 32 cm and was 15 cm deep, was filled with sterile yellowish brown (10YR5/6) redeposited subsoil. Its original form remained unclear because it was cut by a pipe trench on the north and extended out of the excavation area to the south. Although there were no artifacts to date this feature, the eighteenth-century occupation layer (02KC-262) sealed it, indicating it could be quite early.

When all of the archaeological data pertaining to the eighteenth century are examined, several patterns emerge. The first and most obvious is that all of the earliest layers and many of the earliest features must postdate the introduction of creamware to Williamsburg. Even though Josiah Wedgwood first marketed creamware in England, in 1762, it may have taken a little longer to reach Williamsburg. Although a fragment of white salt glaze stoneware recovered from the house's builder's trench indicated that the it could not have been built prior to 1744, the preponderance of creamware in the earliest layers and features would suggest it was constructed even later. Because the likelihood that the house would have remained unoccupied for long after its construction is low, the archaeological data strongly suggest that the Bracken Tenement was built in the late 1760s or early 1770s.

In addition to being present in most of the site's earliest layers and features, creamware was also the predominant eighteenth- and early nineteenth-century 25 ceramic found on the site. The lack of pearlware in the earliest layers and features suggests that the house was first occupied prior to its introduction in 1775, or at least its overwhelming dominance of the ceramic market a few years later. Assuming that the assertion that John Bracken did not acquire the property until at least the middle of the 1780s is correct, then most of these earliest layers and features correspond to an occupation other than John Bracken's. As pearlware became quite popular toward the end of the eighteenth century, it might be possible to use it as a marker to identify possible evidence of John Bracken's ownership. What becomes evident when examining the data is that very little pearlware was actually recovered, especially as compared to creamware. For all contexts, 267 fragments of creamware were found as opposed to only 95 pieces of pearlware, providing a ratio of a little less than three to one in favor of creamware. Furthermore, when the fragments from disturbed or late contexts postdating the middle of the nineteenth century are removed, 180 fragments of creamware and 48 pieces of pearlware were recovered from "good" contexts, for a ratio closer to four to one in favor of creamware.

The unusual pattern here may be related to several factors. One obvious factor that might influence the creamware to pearlware ratio would be the later introduction of pearlware. Not only did pearlware have a slightly shorter manufacture period, layers dominated by pearlware will be stratigraphically higher and therefore, more likely to be disturbed by modern intrusions. However, this does not account for such a lopsided ratio suggesting that there were other factors that led to this pattern.

The lack of features predominated by pearlware makes it difficult to locate John Bracken's ownership of the property. As was known, Bracken most likely did not reside in this house and his usage of it is only speculative. One possible explanation to consider would be that during Bracken's ownership of the property, occupation was sporadic or use of the house was not domestic in nature, accounting for the apparent lack of pearlware (a domestic artifact). Sporadic occupancy might support the idea that Bracken rented his properties and perhaps had trouble keeping them occupied. Another possible explanation would be that the house's occupants were not necessarily interested or able to keep up with the latest ceramic fashions and opted to use older ceramics, such as creamware, even after pearlware had surpassed it in popularity. Comparing these data to archaeological evidence from Bracken's other small properties could prove informative in analyzing these patterns.

Another possible explanation for this artifact pattern is that the yard area was kept relatively clean. Even the earliest layers from the site did not contain overwhelming numbers of artifacts, except in the area of the dripline. Furthermore, the archaeological evidence indicated that occupants of the house used the ditch feature on the east side as a place to dump trash, sometime in the late eighteenth or early nineteenth century. Therefore, the "missing" pearlware might be expected to appear in this feature. However, the ratio of creamware (31 fragments) to pearlware (3 fragments) within the ditch feature was over ten to one, an even higher ratio than for the overall site. This could indicate that much of the trash was being removed to a location even further away from the house. Exploring more of the 26 yard area archaeologically could reveal the presence of a midden to support this idea.

One last characteristic of the artifact deposition pattern is the apparent lack of wine bottle glass. From all of the contexts for which artifacts were saved, only 119 fragments of wine bottle glass were recovered. Without more comparative data, it is virtually impossible to understand whether this is a large or small number. However, wine bottle glass only accounts for 7% of the glass recovered from the site, a percentage which seems small for an artifact which is usually common on eighteenth-century archaeological sites. In comparison, the percentage of wine bottle glass out of the total glass fragments recovered during the waterproofing of William Byrd III's townhouse was 14%, twice the ratio seen at the Bracken Tenement. Furthermore, relatively few wine bottle necks and bases, usually the sturdiest part of the bottle, were recovered. Only one finish and two bases were found, and the majority of the wine bottle glass recovered was in the form of miscellaneous body fragments. These small numbers might suggest that wine bottles were not commonly brought to the house, either because alcohol was not being consumed or the house was not being used for domestic purposes. This pattern might also support the theory that during parts of the house's eighteenth- and early nineteenth-century occupations, trash was being disposed of somewhere away from the house, perhaps in a nearby midden.