Archaeological Excavations of the Bassett Hall Waterproofing Project, Williamsburg, Virginia

Block 1 Building 22-A

Colonial Williamsburg Foundation Research Report Series - 1688

John D. Rockefeller, Jr. Library

Colonial Williamsburg Foundation

Williamsburg, Virginia

2003

Archaeological Excavations of the

Bassett Hall Waterproofing

Project, Williamsburg, Virginia

The Colonial Williamsburg Foundation

Department of Archaeological Research

P.O. Box 1776

Williamsburg, VA 23187-1776

(757) 220-7330

Mark Kostro

Project Archaeologist

Marley R. Brown III

Principal Investigator

November 2002

Management Summary

Between January 2 and April 1 2001, archaeologists from the Colonial Williamsburg's Department of Archaeological Research (D.A.R.) conducted a large-scale archaeological excavation around the perimeter of Bassett Hall (Block 1, Building 22-A) (Figure 1), situated along the south side of Francis Street in Williamsburg, Virginia (Figure 2). The archaeological excavations were prompted by maintenance plans to waterproof the exterior of the building's foundation walls in order to alleviate moisture problems in the structure's basement. The waterproofing of the foundation walls would require the removal of all soils abutting against the foundations, and thus would destroy any intact archaeological layers and features within the impact area. In an effort to salvage the archaeological information before its imminent destruction, archaeological trenches were excavated along the exterior of the structure in each of the areas to be directly impacted by the waterproofing activities. The recovery of archaeological material from Bassett Hall was particularly important, as the historical record for the property is incomplete due to the destruction of the James City County property records during the Civil War.

The excavations in 2001 consisted of several approximately two-meter-wide trenches along the north elevation, around the two chimneys on the structure's east and west gable ends, and along the dining room wing's east elevation. Along the west elevation of the dining room wing, the excavation was expanded to three and a half

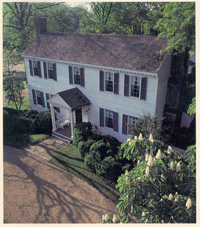

Figure 1. Bassett Hall.

ii

meters in width to correspond with a wider area of impact as indicated by the waterproofing plans. The excavations were conducted following natural stratigraphy until undisturbed subsoil was reached. Each feature was documented and excavated. All soils, with the exception of those from known restoration or post-restoration contexts, were screened through one-quarter-inch hardwire mesh in order to collect any artifacts contained within the soil.

Figure 1. Bassett Hall.

ii

meters in width to correspond with a wider area of impact as indicated by the waterproofing plans. The excavations were conducted following natural stratigraphy until undisturbed subsoil was reached. Each feature was documented and excavated. All soils, with the exception of those from known restoration or post-restoration contexts, were screened through one-quarter-inch hardwire mesh in order to collect any artifacts contained within the soil.

The excavations around Bassett Hall uncovered significant architectural features relating to the construction of, and alterations to, the building over time, as well as cultural layers and features from all phases the building's history. Among the most significant discoveries was evidence that suggests that the original portion of the house was constructed at an earlier date than had been previously thought, possibly as early as the second quarter of the eighteenth century. In addition, the excavations also revealed evidence indicated that the two chimneys located on the gable ends of the original portion of the house were not original to the building's foundations. Other architectural discoveries included a sequence of at least three successive bulkhead entrances into the basement of the house on the east and west sides of the dining room wing, and a brick footing for an early front porch. Non-architectural features that were uncovered included several distinct occupation layers and pathways around the house. Artifacts from the layers and paths formed distinct concentrations and patterns related to the occupants of the house and their activities at Bassett Hall. Among the most unique artifacts recovered was a fragment of window-pane glass, etched with the date commemorating the engagement between Confederate Army officer John W. Lea and Margaret Durfey, the daughter of the then-owner of Bassett Hall.

Figure 2. Location of Bassett Hall.

Figure 2. Location of Bassett Hall.

Overall, the results of the Bassett Hall excavations proved to be an extremely successful example of how limited stratigraphic archaeological excavations can supply valuable new architectural and historical information about a property. Similarly, the excavations have demonstrated that more archaeological, architectural and historical research is necessary in order to understand the property more completely.

ivTable of Contents

| Page | |

| Management Summaryi | |

| List of Figures | vii |

| List of Tables | viii |

| Acknowledgments | ix |

| Chapter 1. Historical Context and Development of Bassett Hall | 1 |

| The Seventeenth Century | 1 |

| The Eighteenth Century | 3 |

| The Nineteenth Century | 15 |

| The Twentieth Century | 21 |

| Chapter 2. Previous Archaeology | 23 |

| Chapter 3. Archaeology in 2001 | 29 |

| Research Design / Methods | 29 |

| Research Results | 30 |

| Eighteenth Century | 30 |

| Nineteenth Century | 57 |

| Twentieth Century | 64 |

| Chapter 4. Conclusions and Recommendations | 67 |

| Conclusions | 67 |

| Suggestions for Further Research68 | |

| Bibliography | 69 |

| Appendices | |

| Appendix A. Master Context List | 73 |

| Appendix B. Bassett Hall Garden Irrigation System Archaeology | 75 |

| Appendix C. Artifact Inventory | 81 |

| 01AC - Bassett Hall Waterproofing | 83 |

| 01AD - Bassett Hall Garden | 136 |

| Page | |

| Figure 1. Bassett Hall | i |

| Figure 2. Location of Bassett Hall | ii |

| Figure 3. Field crew at work during a winter storm at Bassett Hall | ix |

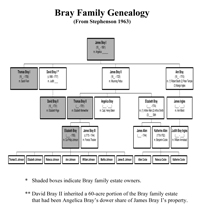

| Figure 4. Bray family genealogy | 2 |

| Figure 5. 1699 Theodore Bland survey of Williamsburg | 3 |

| Figure 6. 1749 Waller Map | 6 |

| Figure 7. Bassett Hall as it appears on the Frenchman's Map (1782) | 11 |

| Figure 8. Bassett Hall as it appears on the Desandrouins Map (1782) | 12 |

| Figure 9. Circa 1790 "College Map" | 14 |

| Figure 10. 1868 plat of Bassett Hall | 18 |

| Figure 11. Late nineteenth-century plat of Bassett Hall | 19 |

| Figure 12. Late nineteenth-century plat of Bassett Hall | 20 |

| Figure 13. Plan of building foundations excavated east of Bassett Hall | 24 |

| Figure 14. Plan of archaeological features within the proposed new parking lot | 26 |

| Figure 15. Locations of archaeological trenches around Bassett Hall in 2001 | 29 |

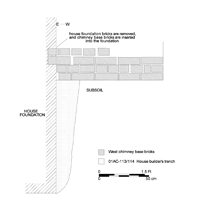

| Figure 16. Profile of Bassett Hall builder's trench under east gable end chimney base | 31 |

| Figure 17. Profile of the north elevation builder's trench, west of the front porch | 32 |

| Figure 18. Scaffolding postholes along north elevation | 34 |

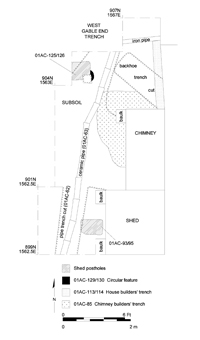

| Figure 19. Shed postholes along west gable end | 35 |

| Figure 20. Plan view of crushed mortar path around the east gable end | 38 |

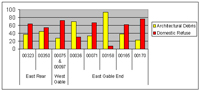

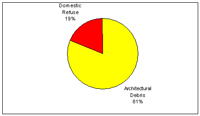

| Figure 21. Comparison of architectural debris vs. domestic refuse from the early occupation layers around Bassett Hall | 40 |

| Figure 22. Architectural debris vs. domestic refuse | 41 |

| Figure 23. Architectural debris vs. domestic refuse | 41 |

| Figure 24. Interface between the west chimney base and the foundation wall | 43 |

| Figure 25. Profile of east chimney builder's trench | 43 |

| Figure 26. Plan view of the brick wall within the west chimney builder's trench | 44 |

| Figure 27. Detail of Frenchman's Map showing "T-shaped" plan of Bassett Hall | 46 |

| Figure 28. Photograph of ditch feature (M2) along the west side of Bassett Hall | 47 |

| Figure 29. Profile of ditch feature (M2) along the west side of Bassett Hall | 48 |

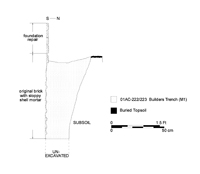

| Figure 30. Profile of the original (east) basement bulkhead entrance | 49 |

| Figure 31. Photograph of the west basement bulkhead entrance | 52 |

| viii | |

| Figure 32. Photograph of a late eighteenth-century repair trench along the north elevation of Bassett Hall | 54 |

| Figure 33. Profile of late eighteenth-century repair trench along the south elevation at Bassett Hall | 54 |

| Figure 34. Photograph of the early north porch footing | 55 |

| Figure 35. Early twentieth-century photograph depicting the two-story north porch | 56 |

| Figure 36. Photograph of the plaster-filled repair trench | 58 |

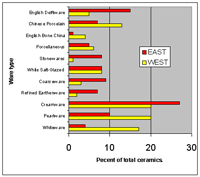

| Figure 37. Distribution of ceramic ware types from the nineteenth-century sheet refuse layers | 61 |

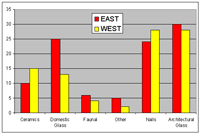

| Figure 38. Distribution of six different artifacts categories from the nineteenth-century sheet refuse layers | 62 |

| Figure 39. Nineteenth-century porch addition | 62 |

| Figure 40. Red-clay-filled boxwood planting hole | 64 |

| Figure 41. Twentieth-century reconstructed porch footing along the east rear of house | 65 |

| Figure 42. Shovel test locations at Bassett Hall garden | 75 |

| Figure 43. Brick foundation at N935/E1550 | 78 |

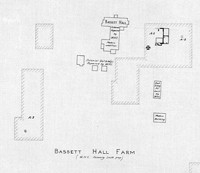

| Figure 44. 1932 Archaeological and Key Map showing colonial outbuildings southwest of Bassett Hall | 79 |

| Page | |

| Table 1. Ceramics from the early occupation layers | 37 |

| Table 2. Ceramics from Master Context 4 | 51 |

| Table 3. Ceramics from Master Context 5 | 53 |

| Table 4. Ceramics from nineteenth-century sheet refuse layers west of Bassett Hall | 59 |

Acknowledgments

The successful completion of the excavation at Bassett Hall was due to the expertise and cooperation of numerous individuals. Marley R. Brown III, the Director of the Department of Archaeological Research, provided general direction and support throughout the project. Staff Archaeologist David Muraca directly supervised the project, and offered his guidance and experience during the course of the excavations and the subsequent analysis. Architectural Historian Michael Bourne lent his considerable expertise on the architectural development of Bassett Hall throughout the duration of the project. Tom Taylor, Architectural Curator, was a frequent visitor, and enthusiastic supporter of the archaeological research, as well as offering his own thoughtful insights on the development of Bassett Hall. The waterproofing crew from Compass Contracting was very accommodating to our excavation schedule, and generous with the use of their excavation equipment in the removal of large quantities of overburden from around the building. Of special note, the successful completion of the fieldwork would not have been possible without the skill and dedication of the hardworking field crew that included: Jason Boroughs, Stacy Mullins, Ryan Remis, Katy Thomason, and Lucie Vinciguerra (Figure 3). All artifacts were processed and inventoried by laboratory technicians Lee Priddy and Isabel Jenkins. Archaeological Collections Curator Bill Pittman and Associate Curator Kelly Ladd assisted with the artifact identification and interpretations. Carrie Alblinger produced the final report graphics.

Figure 3. Field crew at work during a winter storm at Bassett Hall.

Figure 3. Field crew at work during a winter storm at Bassett Hall.

Chapter 1.

Historical Context and Development of Bassett Hall

The Bassett Hall property was part of a large parcel of land patented by the Bray family in the mid-seventeenth century, prior to the founding of the City of Williamsburg in 1699. The historic house and property are located south of Francis Street, within the eighteenth-century boundaries of James City County. Very few records exist for the Bassett Hall property as a result of the burning of the James City County records during the Civil War. The few existing records indicate that the Bassett Hall house was originally constructed at a heretofore-unknown date prior to 1766. Previous researchers have attributed the construction of the Bassett Hall house to Colonel Philip Johnson, whose wife had inherited the property in 1751 (Blackford et al. 1984:17; Buchanan 1980; Stephenson 1959:4). Although research indicates that the building was constructed in the eighteenth century, Bassett Hall draws its name from its well-known early nineteenth-century owner and occupant, Burwell Bassett. In 1927, Dr. W.A.R. Goodwin, on behalf of the Williamsburg Restoration, purchased Bassett Hall as one of the first properties to be acquired in the effort to recreate Virginia's colonial capital. In 1930, a fire severely damaged much of the original structure. Over the next several years, the building underwent extensive reconstruction, and afterward was maintained as the private Williamsburg residence of Mr. and Mrs. John D. Rockefeller. The Rockefeller family retained possession of Bassett Hall until 1979, at which point they donated the house and property to the Colonial Williamsburg Foundation.

The Seventeenth Century

Prior to the establishment of Williamsburg in 1699, the area encompassing Bassett Hall was known as Middle Plantation. Established in 1632/3 by an Act of Assembly, Middle Plantation represented the first interior English settlement on the peninsula (Metz et al. 1998:22). Among Middle Plantation's residents in the second half of the seventeenth century was James Bray I, who had arrived in Virginia from England as early as 1657, and by the following year had brought his wife, Angelica, to the colony as well. James I and Angelica Bray had four children together-Thomas, David, James II, and Ann (Figure 4) (Stephenson 1963:2).

In 1671, Bray purchased 290 acres at Middle Plantation from Henry Wyatt, the son and heir of George Wyatt. The acreage that makes up the Bassett Hall property was once part of this early patent. James I and Angelica Bray and their children were occupying a house on James I's Middle Plantation patent by 1677. Bray rose to prominence in the community, and served as a member of the House of Burgesses between 1670 and 1678, and again in 1688 (Stephenson 1963:2).

In 1676, James Bray I and his wife Angelica had both taken part in the armed rebellion against Governor Berkeley led by Nathaniel Bacon. The rebellion was ultimately suppressed, and many of its participants were severely punished; some were

2

Figure 4. Bray family genealogy.

even executed. Bray and his wife managed to escape execution, although Bray was removed from the House of Burgesses as punishment. Among the less fortunate was William Drummond, a vocal supporter of Bacon, who was hanged for his participation in the rebellion. Drummond's court martial was reportedly held at James Bray I's house at Middle Plantation in 1677 (McCartney 1997:114-122).

Figure 4. Bray family genealogy.

even executed. Bray and his wife managed to escape execution, although Bray was removed from the House of Burgesses as punishment. Among the less fortunate was William Drummond, a vocal supporter of Bacon, who was hanged for his participation in the rebellion. Drummond's court martial was reportedly held at James Bray I's house at Middle Plantation in 1677 (McCartney 1997:114-122).

James Bray I died in 1691, survived by his wife and four children. James Bray I's eldest son, Thomas Bray I, was the primary heir to his father's estate and received the bulk of the 290-acre patent at Middle Plantation, while his widow, Angelica, received a 60-acre portion of the estate as her dower share of her late husband's property. In 1698, Angelica Bray also purchased an additional 190 acres of land (Stephenson 1963:2). Patent research suggests that Angelica Bray's 190-acre patent may have abutted her husband's property to the south (McCartney 2001).

Thomas Bray I married Sarah Fenn, the daughter of Samuel Fenn of Middle Plantation; however, the couple never had any children. In addition to the land inherited via his father at Middle Plantation, Thomas Bray I also acquired additional lands in New Kent County. Between 1698 and 1700, Thomas Bray I was a Vestryman of St. Peters Parish, also in New Kent County, suggesting that he probably resided in that county, and not on his late father's estate at Middle Plantation (Stephenson 1963:4).

3The fact that Thomas Bray I was likely living in New Kent County, and the fact Angelica Bray was purchasing property adjacent to her late husband's patent in 1698, suggests that, after James I's death, Angelica continued to live in her late husband's Middle Plantation home. However, it is not clear whether the house stood on land included in her dower share, or if the house was on land owned by her son Thomas I.

In the final quarter of the seventeenth century, the community at Middle Plantation grew significantly in both size and political strength (Metz et al. 1998:85). The construction of Bruton Church, and the establishment of the College of William & Mary at Middle Plantation, signified the ever-increasing importance of the former inland outpost. Middle Plantation ultimately eclipsed Jamestown as the colony's center in 1699 when the capital was relocated from Jamestown to Middle Plantation. As part of the capital's relocation, a new 220-acre town, to be named Williamsburg, was planned at Middle Plantation between the heads of Archer's Hope (College) Creek and Queen's Creek, straddling the boundary line between James City County and York County (McCartney 1997:135-138).

The Eighteenth Century

As part of the plan for the new capital at Williamsburg, a survey of the town's boundaries was completed by Theodore Bland at the turn of the century (Figure 5). The new town plan was established along a grid, bisected by a one-mile long street (Duke of Gloucester Street) that stretched east from the College of William & Mary to the new Capitol building, with half-acre lots similarly orientated to the new town grid. Trustees of the city purchased land for the new town from the various individuals whose property fell within the newly surveyed town limits. Land was purchased from the estate of

Figure 5. 1699 Theodore Bland survey of Williamsburg.

4

John Page, David Bray I, and Thomas Bray I (or his heirs), among others. The portions of the Bray estate which had not been annexed as part of Williamsburg remained as part of James City County, and abutted the southern limits of the town. The following year, Thomas Bray I died, and because he did not possess any children of his own, his nephew, David Bray II, inherited the family's estate. Meanwhile, Thomas Bray I's lands in New Kent County were inherited by his other nephew, Thomas Bray II (Stephenson 1963:3-4).

Figure 5. 1699 Theodore Bland survey of Williamsburg.

4

John Page, David Bray I, and Thomas Bray I (or his heirs), among others. The portions of the Bray estate which had not been annexed as part of Williamsburg remained as part of James City County, and abutted the southern limits of the town. The following year, Thomas Bray I died, and because he did not possess any children of his own, his nephew, David Bray II, inherited the family's estate. Meanwhile, Thomas Bray I's lands in New Kent County were inherited by his other nephew, Thomas Bray II (Stephenson 1963:3-4).

David Bray II was the only child of Thomas Bray I's younger brother, David Bray I, and his wife Judith. Between 1717 and 1720, David Bray II inherited several hundred additional acres of property following the deaths of his parents. Among the properties were: Angelica Bray's 60-acre dower share of James Bray I's original 290-acre patent, later inherited by David Bray I; 190 acres in James City County originally purchased by David II's grandmother, Angelica Bray in 1698, and also inherited by David Bray I; 300 acres at Tuttey's Neck in James City County originally purchased by Judith Bray; 100 acres in York County, known as Hicks, purchased by David Bray I in 1711; 50 acres in James City County purchased from Thomas Ballard by David Bray I in 1704; 14 acres purchased by David Bray I from Bryan in James City County; and four city lots in Williamsburg (Stephenson 1963:9). As heir to both his father David Bray I's estate and his uncle Thomas Bray I's estate, David Bray II had reunited the majority of his grandfather James Bray I's original 290-acre patent at Middle Plantation (now Williamsburg), with the exception of the land annexed for the founding of the town.

Prior to 1728, David Bray II married Elizabeth Page, the daughter of John Page II of Gloucester. In 1728, following the death of her brother, John Page III, Elizabeth Page Bray was the heir to her family's substantial estate on the north side of Williamsburg (Metz et al. 1997:96). The location of David Bray II and Elizabeth Page Bray's residence is unknown, although it is possible that the couple may have lived in the house formerly occupied by his grandfather, James Bray I, which he had inherited as early as 1700. By 1731, the couple may have been living at "Hicks" in York County, as David Bray II is reported to have died there (Stephenson 1963:9). Elizabeth Page Bray died a few years later in 1734. The couple did not have any children of their own, and thus upon their deaths, the majority of David Bray II's Williamsburg area properties descended to his cousin, Thomas Bray II. Meanwhile, the Page family estate reverted to the heirs of Elizabeth great-uncle, Mathew Page (Metz et al. 1997:96).

Thomas Bray II was the son of James Bray II of Littletown, and Mouring Glen Pettus, the widow of Thomas Pettus. Thomas II's father, James Bray II, owned a large 1280-acre plantation along the James River, southeast of Williamsburg (Kelso 1984:26-27). Thomas Bray II married Elizabeth Meriweather, daughter of Nicholas Meriweather II and Elizabeth Crawford of New Kent County. Thomas Bray II and Elizabeth Meriweather had two children, James III and Elizabeth (Stephenson 1963:10).

In 1725, Thomas Bray II's father, James Bray II, died. In his will, James II stipulated that his daughter, Elizabeth Allen, would have the use of his plantation at Littletown until his grandson, James Bray III, became of legal age. As his inheritance, Thomas Bray II received a plantation along the Chickahominy River, along with some other minor pieces of land. At an unknown date prior to 1732, Thomas Bray II purchased 5 the usage rights to Littletown from his sister, and managed the operations at Littletown until 1736, at which point management of Littletown was transferred to his son, James Bray III, in accordance with the provisions set forth in James Bray II's will (McClure 1977:10-14).

Thomas Bray II's inheritance from David Bray II in 1731 included: the Bray family estate adjoining Williamsburg, originally patented by James Bray I; 190 acres originally patented by Angelica Bray in James City County; 309 acres, known as Grice's, in James City County; 100 acres known as Hicks in York County; 14 acres from Bryan in James City County; 50 acres from Ballard in James City County; four lots in Williamsburg; Black Creek lands in New Kent County; and 1,850 acres, known as Nance's Neck, in Charles City County. Not included as part of Thomas Bray II's inheritance from his cousin was the 300-acre tract of land known as Tuttey's Neck in James City County, which had been originally purchased by Judith Bray. The Tuttey's Neck tract had been bequeathed to David Bray II's business partner John Randolph. A lawsuit ensued, between Randolph and Thomas Bray II over the inheritance of Tuttey's Neck. As a result of the suit, Randolph deeded the Tuttey's Neck property to Thomas Bray II in 1732, in exchange for other Bray family properties, including Grice's, Hicks, and the 14 acres that were originally part of James Bray I's 290-acre tract (Stephenson 1959:2, 1963:9-10, Underwood 1999:24).

The 1749 Waller Map (Figure 6) depicts two of the Williamsburg lots inherited by Thomas Bray II as adjoining Benjamin Waller's lot to the east. The map also identifies "Col. (Thomas) Bray's Land" to the south of "Mr. Benjamin Waller's Pasture." "Col. Bray's Lands" on the Waller Map corresponds with the present-day location of the Bassett Hall property.

In May 1732, Thomas Bray II successfully petitioned the Assembly for the right to sell 60 acres of the 290-acre tract originally patented by James Bray I. The proceeds from the sale of the property were supposed to be reinvested for the benefit of his son, James Bray III. However, an account of the sale was never made, nor are the identities of purchaser(s) of the 60 acres known (Stephenson 1963:10-11).

In 1744, Thomas Bray II's son, James Bray III of Littletown, died without any children of his own. The executors of his estate held a public sale of his personal property (including livestock, household goods, and tools) in October 1744. Littletown and Utopia, however, were reverted back to James III's father, Thomas Bray II. While keeping possession of Littletown, Utopia was given to James III's widow, Francis Thacker Bray, as part of her dower right (McClure 1977:15).1

As the only surviving male Bray heir, Thomas Bray II had amassed a substantial quantity of land in James City County and Williamsburg. Thus, determining where Thomas Bray II lived is a potentially complicated endeavor. It is known that Thomas Bray II's father had built a large mansion at Littletown soon after 1700, and owned a brick town house in Williamsburg (Kelso 1984:37). As a youth, Thomas Bray II most likely lived on his father's Littletown property, while the brick town house in Williamsburg

6

Figure 6. 1749 Waller Map.

7

was likely only used when James Bray II was in Williamsburg serving as a member of the House of Burgesses, or as alderman for the City of Williamsburg. The city lots and the brick house were to be sold upon his death, thus Thomas Bray II likely would not ever have resided there. Shortly after his father's death, Thomas Bray II had obtained the usage rights to Littletown from his sister, Elizabeth Allen. Thus, it remains likely that for the period after his father's death in 1725, Thomas Bray II probably continued to live at Littletown until around 1736, when his son became old enough to take possession. Once his son had taken over managing the operations there, Thomas Bray most likely moved away from Littletown to one of his own properties. Although he managed Littletown's operations until 1736, Thomas Bray II's may have moved to Williamsburg as early as 1731, when he inherited from his cousin, David Bray II, the remainder of 290-acre Bray family estate (present-day Bassett Hall). For the decade of the 1730s it is unclear where Thomas Bray II was living; however, by 1744, letters addressed to Thomas Bray II suggest that he was living in Williamsburg. On December 26, 1744, Carter Burwell executor of James Bray III's will, wrote to Thomas II, addressing the letter to "Col Bray at Williamsburgh" (Stephenson 1963:10).

Figure 6. 1749 Waller Map.

7

was likely only used when James Bray II was in Williamsburg serving as a member of the House of Burgesses, or as alderman for the City of Williamsburg. The city lots and the brick house were to be sold upon his death, thus Thomas Bray II likely would not ever have resided there. Shortly after his father's death, Thomas Bray II had obtained the usage rights to Littletown from his sister, Elizabeth Allen. Thus, it remains likely that for the period after his father's death in 1725, Thomas Bray II probably continued to live at Littletown until around 1736, when his son became old enough to take possession. Once his son had taken over managing the operations there, Thomas Bray most likely moved away from Littletown to one of his own properties. Although he managed Littletown's operations until 1736, Thomas Bray II's may have moved to Williamsburg as early as 1731, when he inherited from his cousin, David Bray II, the remainder of 290-acre Bray family estate (present-day Bassett Hall). For the decade of the 1730s it is unclear where Thomas Bray II was living; however, by 1744, letters addressed to Thomas Bray II suggest that he was living in Williamsburg. On December 26, 1744, Carter Burwell executor of James Bray III's will, wrote to Thomas II, addressing the letter to "Col Bray at Williamsburgh" (Stephenson 1963:10).

Thomas Bray II died in 1751, leaving his daughter, Elizabeth Bray Johnson, as the heir to the family estate. Elizabeth was the wife of Colonel Philip Johnson, whom she had married in 1743. The couple had seven children: Thomas B., Elizabeth, Rebecca, Ann, William, Martha, and James B. (Stephenson 1959; 1963:17).

Upon Thomas Bray II's death, a lawsuit ensued concerning the division of his estate. This lawsuit pitted the John sons against William Armistead and his wife, Judith Bray Armistead. The issue was ultimately resolved in 1753, and as part of the settlement, William and Judith Bray Armistead were awarded the Bray family property known as Nance's Neck in Charles City County, and two lots in Williamsburg adjoining the lots of Dudley Digges and James Spiers. Meanwhile, Philip and Elizabeth Bray Johnson were awarded the 290-acre Bray family estate, 300 acres at Tuttey's Neck, and two lots in Williamsburg between Benjamin Harrison and Benjamin Waller (Stephenson 1959:2-3). The lots awarded to Philip and Elizabeth Bray Johnson are the same lots shown as belonging to Thomas Bray II on the 1749 Waller Map (see Figure 6). By 1758, as a condition of Elizabeth Bray Johnson's inheritance from her father, portions of the estate would be vested in trust to John Robinson for the benefit of Elizabeth Bray and Col. Philip Johnson's children. In addition, the will further indicated that Col. Philip Johnson would have a life right to the Bray family estate if Elizabeth should precede him in death (Stephenson 1959:4, 1963:18).

For the decade of the 1750s, there exists no documentary evidence to specify if Elizabeth Bray Johnson and her husband Philip Johnson were living on the property inherited from Elizabeth's father, Thomas Bray II. Separate from Elizabeth's inheritance, Philip Johnson also owned a plantation in King and Queen County. Colonial documents indicate that for the years 1752-1755 and 1756-1758, Johnson is known to have served as a Burgess from King and Queen County. It is very likely that Johnson was maintaining a residence in Williamsburg during this period for use while the Burgesses were in session, in addition to a residence at his King and Queen County plantation (Stephenson 1959:4).

8Although the residence of Col. Philip and Elizabeth Bray Johnson in Williamsburg remains speculative for the decade of the 1750s, records of their use and management of the property do exist. On April 4, 1755, the property is cited in the Virginia Gazette:

NOTICE is hereby given; THAT there is a good Stable and Pasture, with all Sorts Of Provinder for Horses, at the Plantation of Philip Johnson, near the Capitol in Williamsburg; where Gentlemen may depend on having proper Care given of their Horses, Carriages, &c (cited in Stephenson 1959:3).

The identification of Johnson's property as a "plantation" implies that agricultural production was occurring at that location, in addition to stabling horses and carriages. More than likely, agricultural production was the main use of the property, while the service of stabling horses was an attempt by Johnson to develop a supplementary business. The operation of the stable, and the plantation, would likely have required a substantial work force. These tasks were more than likely fulfilled by a contingent of slaves managed by one or more overseers. Several slaves owned by Johnson were baptized in Bruton Parish between 1751 and 1768 (Stephenson 1959:4).

By the middle of the eighteenth century, Williamsburg had grown from a scattered community into a bustling urban center. In addition to being the colony's capital, Williamsburg was increasingly becoming a commercial center. Merchants and craftsmen had established successful businesses at locations throughout the city. Certain enterprises were also known to cluster together within a particular part of the city to take advantage of, as well as compete for, a specific clientele. In particular, businesses such as taverns and stables were commonly established near the area known as "The Exchange," adjacent to the Capitol on the east side of Williamsburg (Reps 1972:179). Although outside the area of the Exchange, Johnson similarly attempted to take advantage of his plantation's close proximity to the colony's capitol, by providing a needed service to those attending to business at the nearby capitol and the Exchange.

One consequence of the city's growth was that living conditions in Williamsburg were becoming increasingly overcrowded. The demand for cheap land within the city was recognized by several individuals as an opportunity to make money. In 1750, Matthew Moody created a new subdivision, on the land west of Capitol Landing Road and north of the city. Similarly, on the east end of Williamsburg, behind the capitol, Benjamin Waller subdivided his property and sold off the individual lots (Richards 2001:21; Metz et al. 1998:99; Reps 1972:183). In 1758, Philip Johnson attempted to replicate the successes of Moody and Waller, and petitioned to acquire a parcel of land controlled by John Robinson, trustee of the Bray family estate, consisting of 19 acres and 26 poles, adjoining to the bounds of Williamsburg to the south. In exchange for these lands, Johnson agreed to transfer 43 acres of his own land into the trust held by Robinson. Johnson's intent was to sub-divide the 19 acres and 26 poles of land into 32 lots to be sold individually, and to be incorporated into the City of Williamsburg. Johnson's petition was approved, and by 1761, the property had been divided into 34 lots.2 Late eighteenth-century maps of Williamsburg depict Johnson's 9 subdivision was located west of the modern-day Bassett Hall, and are numbered as lots 1 through 34 (Reps 1972:183; Stephenson 1959:4).

In 1765, Elizabeth Bray Johnson died, and as previously mentioned, Philip Johnson was entitled to a life right of her property. As early as October 1765, Johnson advertised his late wife's family estate for rent, according to an entry in the Virginia Gazette Day Book. In the summer of 1766, the estate was apparently still without a tenant, and on June 6, 1766 the following advertisement appeared in the Virginia Gazette:

TO BE RENTED

June 6, 1766

THE houses, lots, gardens, stable, and pasture, where I lately lived, adjoining the City of Williamsburg, Any person inclinable to rent them for a year, or term of years, may know the terms by applying to Doctor Hay, or Philip Johnson .(cited Stephenson 1959:5)

From the above notice, it is clear that Johnson had lived on the property inherited from his father-in-law prior to 1766, albeit for an unknown duration. Upon Elizabeth's death, Johnson moved out of Williamsburg, possibly preferring to live on his own plantation, Vaux Hall, along the Chickahominy River. Johnson's advertisement for the rental of the Bray estate indicates that the property included at least one dwelling house, gardens, a stable, and a pasture. The mention of a dwelling house in the notice represents the first documentary reference to a house associated with Johnson's plantation being situated on the property. Because of no specific mention of a dwelling house at Bassett Hall prior to the notice, previous researchers have speculated that the house did not exist until shortly before the advertisement's publication. Accordingly, the construction of the dwelling house has been typically attributed to Philip Johnson and his wife, Elizabeth Bray Johnson, possibly at around 1760 (Blackford et al. 1984:17; Buchanan 1980; Stephenson 1959:4).

In 1769, John Robinson, who had held the Bray estate in trust for the benefit of Elizabeth Bray and Col. Philip Johnson's children, died. Thus, new trustees were appointed to hold the property. In that year the property was described as,

...one messuage, and three hundred and twelve acres of land, adjoining to the city of Williamsburg, except nineteen acres, and twenty-six poles, laid off into lots, and annexed to the city of Williamsburg... also of forty-three acres, purchased by Philip Johnson, gentleman, of John Baskerfield, also of six hundred acres, with the appurtenances, called and known by the name of Tutty's Neck, and also of two lots or half acres of land on Francis street, in the city of Williamsburg.... (cited in Stephenson 1959:6).

Although advertised for rent as early as 1765, no documentary evidence survives that indicates that Johnson succeeded in renting the property until 1771. Who occupied the property between 1765 and 1771 remains unclear. Beginning in 1771, Richard Hunt Singleton was a tenant at the Bray family estate. On March 7, 1771, the following advertisement appeared in the Virginia Gazette:

WILLIAMSBURG, March 7, 177110

THE Subscriber begs Leave to acquaint the Gentlemen Who favoured him with their Custom that he is now Removed to Colonel Johnson's house, behind that of Mr. Waller; where they may depend upon the best Accommodations for themselves, Servant, and Horses.

RICHARD HUNT SINGLETON. (cited in Stephenson 1959:7)

While renting Col. Johnson's house, the advertisement indicates that Singleton operated a boarding house or possibly a tavern at the property, including accommodations for servants and horses. Among Singleton's boarders in 1771 was Francis Russworm, a music teacher. Russworm apparently taught music lessons at the house, and placed the following advertisement in the Virginia Gazette:

BEGS Leave to acquaint the young Gentlemen in and about Williamsburg that he shall open School on Monday the 3d Of June, at Mr. Singleton's Hose, to teach the VIOLIN, GERMAN and COMMON FLUTES...(cited in Stephenson 1959:7)

Financial problems appear to have plagued Johnson in his later years, in spite of (or possibly on account of) his varied entrepreneurial endeavors (e.g., stabling horses, land development, etc.). Johnson's desire to rent the Williamsburg property inherited by his late wife may have been in an attempt to alleviate these financial woes. On April 14, 1768, Johnson posted the following notice in the Virginia Gazette:

THIS is to request the favour of all my Creditors to Meet me at the brick house of Mr. Gabriel Maupin, in Williamsburg, the second day of next month...

Philip Johnson

(cited in Stephenson 1959:6)

In an effort to collect debts owed by Johnson, the trustees of Bray family estate advertised the property for sale in the Virginia Gazette in October 1771. The sale was advertised in spite of the fact that Johnson had succeeded in renting the property to Richard Hunt Singleton in early 1771.

WILLIAMSBURG, OCTOBER 1, 1771.

PURSUANT to a late Act of the General Assembly, which Hath received the royal Assent, we propose to sell to The highest Bidders, on Thursday the 31st Instant, at Four oClock in the Afternoon, before Mr. Southall's Door, in this City, the DWELLING-HOUSE, OUTHOUSES, GARDEN, and PASTURE, where Colonel Philip Johnson formerly lived, now in the Tenure of Mr. Richard Hunt Singleton; also the Remainder of the same Tract of LAND Adjoining the City of Williamsburg, with two LOTS On Francis Street, between the LOTS of Mr. Waller and Doctor Pasteur; the whole to be disposed of together, Or in Parcels, as may best suit the Purchasers...

PEYTON RANDOLPH

(cited in Stephenson 1959:8)

RO. C. NICHOLAS Trustees

LEWIS BURWELL

PHILIP W. CLAIBORNE

For an unknown reason, the Trustees of the estate were unsuccessful in selling the property in Williamsburg. The property was again advertised for sale in April 1773, but continued to remain unsold (Stephenson 1959:10). Singleton continued to rent the property in until 1773. In January of that year, Singleton moved from the Bray estate to the Brick House Tavern on Duke of Gloucester Street in Williamsburg (Stephenson 1959:9).

Johnson's problems with his creditors continued, and in 1777 the Trustees of Johnson's property advertised to meet with Johnson's creditors to attempt to settle his accounts. In that same year, Johnson's own plantation, Vaux Hall, was also listed for sale in the Virginia Gazette (Stephenson 1959:10). Nevertheless, in spite of his financial 11 difficulties, Johnson continued to be active in local politics. Between 1773 and 1776, he served as a Justice of James City County, but had to resign his post on the account of age and infirmities (Stephenson 1959:11; McCartney 1997:215).

The documentary record remains silent as to the identity of the occupants of Bassett Hall for the period after Richard Hunt Singleton moved out. In 1788, new trustees for the property were appointed on behalf of Elizabeth Bray Johnson's husband and their children, because all the previously appointed trustees had died. The appointment of the new trustees suggests that the estate had not been sold during the intervening period. According to a notice in the Virginia Gazette, Philip Johnson died the following year, in 1789 (Stephenson 1959:12).

At the time of the American Revolution, two different maps of Williamsburg and its environs were produced and depict the layout of various buildings on the property as they existed in the early 1780s. Produced by an anonymous cartographer, the Frenchman's Map (1782) depicts a large rectangular structure orientated on an east-west axis with a rear addition, orientated north-south, extending off the center of the main portion of the building, to give the building a "T-shaped" plan, which was located approximately 400 feet to the south of Francis Street on the Bassett Hall property (Figure 7).

The "T-shaped" building on the map is undoubtedly the same building known today as Bassett Hall, and the dwelling referred to in Philip Johnson's 1766 rental notice. Previous architectural research suggests that the original plan of the house was a one-room-deep rectangular structure, with a central hall dividing two rooms on the first floor. It was further suspected that the original house was most likely one-and-a-half

Figure 7. Bassett Hall as it appears on the Frenchman's Map (1782).

12

stories, and later raised to two-stories, as indicated by the differences in the window treatment on the first and second floors (Buchanan 1980). By 1782, however, the outline of the building had evolved into a "T-shaped" plan, with the addition of the rear wing. Although it is clear that the rear addition to the original structure had been completed prior to 1782, the actual date of the rear addition's construction remains unknown. The architectural research also suggests that the rear addition was also originally one-and-one-half stories in elevation, but was raised to two stories in the nineteenth century (Buchanan 1980). Finally, in addition to the dwelling house, three outbuildings are depicted immediately south of the main structure on the Frenchman's Map. A fourth outbuilding is shown southeast of the main structure, and a fifth outbuilding is shown to the southeast, approximately 350 feet away from the house.

Figure 7. Bassett Hall as it appears on the Frenchman's Map (1782).

12

stories, and later raised to two-stories, as indicated by the differences in the window treatment on the first and second floors (Buchanan 1980). By 1782, however, the outline of the building had evolved into a "T-shaped" plan, with the addition of the rear wing. Although it is clear that the rear addition to the original structure had been completed prior to 1782, the actual date of the rear addition's construction remains unknown. The architectural research also suggests that the rear addition was also originally one-and-one-half stories in elevation, but was raised to two stories in the nineteenth century (Buchanan 1980). Finally, in addition to the dwelling house, three outbuildings are depicted immediately south of the main structure on the Frenchman's Map. A fourth outbuilding is shown southeast of the main structure, and a fifth outbuilding is shown to the southeast, approximately 350 feet away from the house.

A second Williamsburg map, produced ca. 1782, was drafted by French engineer Jean Nicholas Desandrouins (Figure 8). Although covering a much greater area than the Frenchman's Map, the Desandrouins map also depicts significant detail about the location of structures around Williamsburg. The map features a large main structure set back from Francis Street approximately 400 feet. The map, however, does not provide any detail about the plan shape of the structure, although as many as eight different outbuildings are also depicted on the map to the south of the main structure. To the west of the main structure, the map illustrates what appears to be a large enclosed garden area.

Figure 8. Bassett Hall as it appears on Desandrouins Map (1782).

Figure 8. Bassett Hall as it appears on Desandrouins Map (1782).

Earlier maps (see Figure 6) indicate that the area between the house and the street was within the city limits of Williamsburg, and had been subdivided into two lots. From the documentary record, it remains clear, however, that the lots were included as part of the Bray family estate (Bassett Hall property). According to both maps the lots were not built upon, an important clue to the landscape development of the property and the status of its owners. The unobstructed view from Bassett Hall through the lots would have provided for a park-like vista, extending north from the house's front steps. Following Georgian concepts of architecture and landscape design, popular in eighteenth-century Virginia, expansive vistas were a highly desired landscape feature among the wealthy and elite citizens of Williamsburg (Reps 1972:180).

After the Revolutionary War, the capital was moved west from Williamsburg to Richmond, reflecting the increasing importance of western expansion. The effect of the capital's removal was a virtual stagnation of the growth that had marked Williamsburg's previous eighty years. Williamsburg's slowed economy, after the capital's relocation, is likely to have contributed to Philip Johnson's difficulties in renting or selling his property in Williamsburg.

Prior to 1794, and possibly as early as 1789, Richard Corbin of "Laneville" in King and Queen County became the owner of the Bassett Hall. Corbin's mother, Molly Waller Corbin, was the daughter of Judge Benjamin Waller of Williamsburg. Corbin most likely purchased the property from the trustees who were representing Elizabeth Bray and Philip Johnson's children. Corbin was likely very familiar with the property before he purchased it, as his uncle Robert Hall Waller lived next door in the Benjamin Waller House (Stephenson 1959:12-13; Richards 2001:1).

Corbin carried out extensive repairs to the building between 1794 and 1795, employing various local carpenters, blacksmiths and brick masons in the course of the repairs. The extensiveness of the repairs suggests that the house had fallen into considerable disrepair by the final decade of the eighteenth century. In addition to the repairs made to the house, Corbin also purchased a large quantity of new furnishings and drapery from Williamsburg, Richmond, and Philadelphia merchants for his new home (Stephenson 1959:13-14). Soon after the repairs to the house were complete, Corbin returned to Laneville and negotiated to sell his newly refurbished home to Burwell Bassett of Eltham in New Kent County (Stephenson 1959:15).

Burwell Bassett was born on March 18, 1764, the son of Burwell Bassett and Anna Maria Dandridge, the daughter of John Dandridge, and sister of Martha Washington. The Bassetts were among the most prominent families of the Virginia colony. Burwell Bassett's forbearers for the previous five generations had been Burgesses or members of the Governor's Council. Burwell Bassett continued his family's tradition of involvement in government, as a member of the House of Delegates between 1787 and 1789; as a member of the Senate between 1793 and 1805; as a member of Congress between 1805 and 1813; again as a member of the House of Delegates between 1819 and 1821; and finally again as a member of Congress between 1821 and 1829. On January 10, 1788, Burwell Bassett married Elizabeth McCarty, daughter of Daniel McCarty of Pope's Creek, Westmoreland County. Bassett was later remarried to Anne Claiborne, the daughter of William Dandridge Claiborne of Liberty Hall, King William County, and Euphania Claiborne (Stephenson 1959).

14According to the "College Map," which probably dates to the early to mid 1790s, Bassett owned six lots in the city of Williamsburg (Figure 9). Two of the lots lay on the south side of Francis Street, between the lot owned by Semple to the west and Waller to the east. The Bassett Hall property is located immediately south of these lots within James City County. These are undoubtedly the two lots Elizabeth Bray Johnson had inherited from her father, and were considered as part of the Bassett Hall property to the south. The remaining four lots (lots 16-19) adjoin the Bassett Hall property to the west within the sub-division originally laid out by Col. Philip Johnson and annexed to

Figure 9. Circa 1790 "College Map".

15

the city in 1758. Lots 16 and 17 are also identified on the map as belonging to "N. Harrison" along with Burwell Bassett. It is unclear if both owned title to these lots together, or if they had further subdivided these lots between themselves. The map further situates "Col. Philip Johnson's Land" south of the sub-division, within James City County. It is also unclear if this refers to additional Bray family lands used by Johnson, or his own land adjacent to the Bray family estate (Stephenson 1959:12).

Figure 9. Circa 1790 "College Map".

15

the city in 1758. Lots 16 and 17 are also identified on the map as belonging to "N. Harrison" along with Burwell Bassett. It is unclear if both owned title to these lots together, or if they had further subdivided these lots between themselves. The map further situates "Col. Philip Johnson's Land" south of the sub-division, within James City County. It is also unclear if this refers to additional Bray family lands used by Johnson, or his own land adjacent to the Bray family estate (Stephenson 1959:12).

The Nineteenth Century

Tax records for the City of Williamsburg indicate that Burwell Bassett lived in James City County and was taxed for two lots in Williamsburg between 1804 and 1811. The total value of the lots was $20 in 1804 and 1806, but the value dropped to $10 between 1807 and 1811. Once again, these are likely the two lots on Francis Street, directly north of the Bassett Hall property. Between 1812 and 1819, Bassett was taxed for four additional lots within the city, for a total of six lots (total tax $30). Based on the "College Map," these lots are likely Williamsburg lots 16 though 19, located west of the Bassett Hall property, within the Johnson sub-division. Between 1820 and 1838, Burwell Bassett was charged for only one lot valued at $75. It is possible that the two lots on Francis Street, situated in front of Bassett Hall, were combined into a single entity. In 1840, Bassett was taxed for one lot valued at $100, but his county of residence changed from James City County to New Kent County. In 1838, Burwell Bassett returned to his ancestral home at Eltham in New Kent County, but continued to own Bassett Hall for another two years. In 1841 and 1842, Burwell Bassett's estate is taxed for one lot in Williamsburg, also at $100 (Stephenson 1959).

Unfortunately, the earliest James City County tax records to survive for the property are not until 1813. In that year, Burwell Bassett was taxed for 335 acres. The following property description is contained in the tax records:

Bounded by Williamsburg Stage Road on N. the Road to King's Mill on the E Tutters Neck Mill Run & Saunders tract on the S & Littleton Tazewells on the W (cited in Stephenson 1959).

The 335 acres listed in the above 1813 description closely matches the 1769 description of the acreage for the property inherited by Elizabeth Bray Johnson and held in trust for Philip Johnson and their children. In 1769, the property was listed as equaling 311 acres, minus the 19 acres and 26 poles subdivided by Philip Johnson in 1758. In exchange for the 19 acres and 26 poles of land, Johnson agreed to place in trust for his children 43 acres of his own land. As a result of the transaction, the total acreage of the property held in trust had increased to approximately 335 acres. Therefore, based on the above-mentioned descriptions, the size of the Bassett Hall property did not change during the 44-year period between 1769 and 1813. Burwell Bassett continued to be taxed for 335 acres for another 21 years until 1834. During that period, the total value of the land and buildings remained constant at $5849.10. In 1835, the size of the property was reduced to 329 acres. The tax records indicate that six acres were taken from the Bassett Hall property, and charged to Richard M. Bucktrout (Stephenson 1959).

16As a son of one of Virginia's wealthiest and prominent families, Burwell Bassett entertained numerous public figures, politicians, and artists at Bassett Hall. Among Bassett's guests at Bassett Hall was the noted Irish poet Thomas Moore (1779-1852). Moore is said to have been a guest at Bassett Hall, when he stopped by en route from Norfolk to Richmond in 1804. Local legend states that Moore was so inspired by the fireflies, which he observed flittering through the gardens at Bassett Hall, that he wrote the following poem (Stephenson 1959:16; Blackford 1984:18; Williamsburg Garden Club 1950:46-47):

To The Firefly

At morning when the earth and sky,

Are glowing with the light of spring,

We see thee not, thou humble fly,

Nor think upon thy gleaming wing.

But when the skies have lost their hue,

And sunny lights no longer play,

Oh then we see and bless thee, too,

For sparkling o'er the dreary way.

Then let me hope, when lost to me

The lights that now my life illume

Some milker joys may come like thee,

To cheer, if not to warm, the gloom.

In 1817, while living at Bassett Hall, Burwell Bassett also rented the neighboring Waller property on behalf of his mother-in-law, Euphania Claiborne. Bassett continued to rent the Waller house, on behalf of his mother-in-law, until 1820 (Richards 2001:8; Stephenson 1959:16)

On May 5, 1840, Judge Abel Parker Upshur purchased Bassett Hall from Burwell Bassett. In October 1841, President John Tyler appointed Upshur to his cabinet as the thirteenth Secretary of the Navy. Two years later, Upshur was appointed as Secretary of State by President Tyler upon the resignation of Daniel Webster. As Upshur's responsibilities increased in Washington, he no longer required his residence in Williamsburg, which he sold to John Coke in 1843.3 John Coke only held the property for only a short while, selling it to Goodrich Durfey on November 18, 1845 (Stephenson 1959:18-19).

By 1857 the size of the Bassett Hall property was listed as including 381 acres. The discrepancy between the size of the property in 1835 (329 acres) and 1857 (381 acres) remains unaccounted for. In that same year, Goodrich Durfey sold a 296-acre portion of the Bassett Hall property to William Lyon. According to later plats of the property, the 296-acre tract sold to Lyon consisted of approximately the eastern three-fourths of the total Bassett Hall property, but did not include an 85-acre strip of land that included the land surrounding the house and outbuildings. Lyon, however, had difficulties making his payments for the purchase of the property, and in 1865 the 296-acre tract was conveyed back to Goodrich Durfey (Stephenson 1959:19-20).

The Durfeys were living at Bassett Hall when the Civil War erupted. On May 5, 1862, the Battle of Williamsburg was fought between the Union and Confederate 17 armies just beyond the Bassett Hall estate, southeast of the city. At nightfall on May 5, after a hard-fought battle, the Confederate army abandoned its positions and retreated up the peninsula to Richmond. While pursuing the retreating Confederate army, the Union forces seized Williamsburg, and the city remained under Union control for the duration of the war (Hastings and Hastings 1997:117). The Durfey family were one of many Williamsburg families to care for the wounded Confederate soldiers in their homes after the battle (Rouse 1989:97).

Goodrich Durfey continued to own Bassett Hall until his death in 1869. According to a deed dated on December 15, 1869, and recorded on January 4, 1870, the executors of Goodrich Durfey's will sold the Bassett Hall property to Isreal Smith for the purchase amount of $8000.00 (Stephenson 1959:20). The deed describes the property as follows:

...that Certain tract or parcel of land Situate partly in the City of Williamsburg and partly in the county of James City, State of Virginia, called "Bassetts Hall," containing about three hundred and eighty one acres, more or less, bounded as follows - Commencing on the north, at the north East Corner of James W. Custis' lot, thence along the Street to the lot Occupied by Dr. Wm S. Morris, thence South to the Corner of said Morris's lot thence east along ditch separating it from said Morris's lot and James Mahone, John Lucas and Charles Lively's lots to the road leading from Wmsburg to York Town, thence along said road to the road Called quarter paths, thence along last mentioned road to the middle of Tutters neck Dam, thence South west to fence separating it from 'Delks', thence north to fence on the farm, thence southwest to corner of Munford's fence Thence North west along said Munford's fence to the Corner of Dr. Camm's land, thence along ditch bank & fence separating it from said Camm's land to the lot formerly owned by R.M. Bucktrout, Decd thence east to the of said Bucktrouts lot and, thence north to the beginning as will appear by reference to the plot of W.I. Morrsett, markd B. and being part of the tract which the said Goodrich Durfey, in his life time purchased of John Coke and Eliza his wife as aforesaid, and the same first mentioned in the will of the said Goodrich Durfey, Decd.... (cited in Stephenson 1959).

In the late nineteenth century, several plats of the Bassett Hall property were produced that have provided important information about the layout, boundaries and buildings located on the Bassett Hall property. The first plat, with the date 1868 written on the back, shows the extent of the property boundaries and a dwelling at the current location of Bassett Hall, with a driveway leading from the house to Francis Street (Figure 10). The plat further delineates the boundaries of the 296-acre tract previously sold to William Lyon in 1857, and returned to Goodrich Durfey in 1865 (Stephenson 1959:19).

The second plat of the property is unfortunately undated, but shows considerable detail about land use, the identities of neighbors, and the locations of structures on the property (Figure 11). The house is shown with a "T-shaped" plan, facing upon a two-acre lawn. A circular driveway is depicted in front of house, as well as numerous farm roads traversing through various parts of the property. The plat also indicates numerous divisions within the property: farmlands, gardens, orchards, barns, an ice house, a hog pen, cow yard, and pastures. Neighboring Bassett Hall are the lands of J.W. Custis to the northwest, Dr. Camm to the west, Col. Mumford to the southwest, and Dr. Morris to the northeast (Stephenson 1959).

18 Figure 10. 1868 plat of Bassett Hall (from Stephenson 1959).

Figure 10. 1868 plat of Bassett Hall (from Stephenson 1959).

Figure 11. Late nineteenth-century plat of Bassett Hall (from Stephenson 1959).

Figure 11. Late nineteenth-century plat of Bassett Hall (from Stephenson 1959).

A third plat is also undated, and appears to have been a copy of the second plat, although with considerably less detail (Figure 12). The dwelling house with its circular driveway, outbuildings, gardens and orchards, and farm roads are all shown on the plat. J.W. Custis, Col. Mumford, and Dr. Morris are all indicated as neighboring property owners (Stephenson 1959).

Israel Smith died in 1879, at which point the property was passed to various members of the Smith family. The Smith family retained ownership of Bassett Hall until 1927 when it was acquired by Colonial Williamsburg (Stephenson 1959:20).

Figure 12. Late nineteenth-century plat of Bassett Hall (from Stephenson 1959).

Figure 12. Late nineteenth-century plat of Bassett Hall (from Stephenson 1959).

The Twentieth Century

In 1927, Dr. W.A.R. Goodwin, on behalf of the Williamsburg Restoration, purchased Bassett Hall as one of the first properties acquired in the effort to recreate Virginia's colonial capital. Only a few years after Goodwin purchased Bassett Hall, on May 16, 1930, the house was struck by lightning, igniting a devastating fire that severely damaged much of the original structure. Subsequently, the building was restored with additions to the rear of the structure to accommodate a modern kitchen and butler's pantry. Beginning in 1936, after the renovations were completed, the house was maintained as the private Williamsburg residence of Mr. and Mrs. John D. Rockefeller. The Rockefeller family donated Bassett Hall to the Colonial Williamsburg Foundation in 1979 (Blackford et al. 1984).

Chapter 2.

Previous Archaeology

The earliest archaeological investigation of the Bassett Hall property occurred in the late fall of 1930. A work order, dated December 12, 1930 from the architectural firm of Perry, Shaw and Hepburn authorized "Messrs, Todd & Brown" to excavate the Bassett Hall property without screening. Unfortunately, there exists no documentation of the extent, or results of, Todd & Brown's excavations. Nevertheless, from subsequent correspondence, it is clear that Todd & Brown conducted excavations along the rear or south side of the main dwelling house (Building 22-A); although the extent of their excavations around the remainder of the building remains unknown. It has been speculated that the work conducted by Todd & Brown more likely consisted of the dismantling of the fire-damaged portions of the standing structure, rather than conventional archaeology as it is known today. Ultimately, the results of their excavations had a significant impact on the restoration of the building. According to a correspondence dated February 3, 1931, between the firm of Perry, Shaw and Hepburn and the Williamsburg Holding Corporation, a "Change Order" was submitted altering the original plans for the structure's restoration, recommending, "...an enlargement of the chimney to agree with archaeological evidence discovered upon razing the modern chimney... necessary for an authentic restoration" (Anonymous ca. 1983).

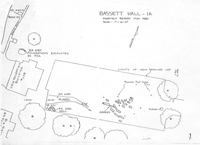

There exists no evidence of any subsequent archaeological work around the dwelling house at Bassett Hall. Archaeological investigations, in the form of cross-trenching, did however take place elsewhere on the Bassett Hall property beginning in 1932 under the supervision of Herbert S. Ragland. The strategy for selecting areas for the cross-trenching was based the locations of structures as indicated on the Frenchman's Map. Further considerations regarding the locations of the excavations were made in order to not disturb, or inconvenience, the tenants living at Bassett Hall (Anonymous ca. 1983). According to The Archaeology and Research Key Map of the Restoration Area, Williamsburg, Va. (1932, Revised 1933), the areas investigated included five variously-sized areas to the east, west and south of the main dwelling house. The results of the cross-trenching were briefly summarized in a two-page report by Ragland in 1932.

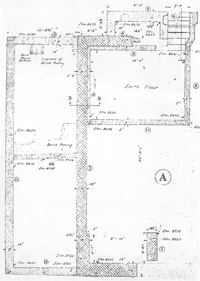

Most significant among Ragland's findings was a large two-brick-wide foundation (1-A-1) located 80-feet east of the Bassett Hall main dwelling house (Figure 13). The foundation showed evidence of two periods of construction, using large bricks (9 x 4.5 x 2.5 feet) in English bond with shell mortar. In the northeast corner of the structure, a large (8 feet 10 inches wide x 4 feet 8.5 inches deep) interior chimney was recorded. A second smaller exterior chimney was also recorded along the southern end of the structure, and may have been part of a later addition. A cellar underlies the southern third of the structure, and was evidently excavated after the original foundations were in place. The footings of the original foundation walls were three feet above the floor of the cellar. The plan drawing of the foundations indicates that the floor

24

Figure 13. Plan of building foundations excavated east of Bassett Hall (from Ragland 1932).

25

within the cellar was earthen. Access into the cellar was gained through a bulkhead entrance west of the southern chimney. The bulkhead had also been added after the original foundations had been constructed. Attached to the east side of the original structure was a one-and-a-half-brick-wide foundation for a two-roomed addition. Evidence of brick paving was noted in the southern room, but not in the northern room. The plan drawing also indicates a brick-lined sump along the south wall of the brick-paved room within the addition. Numerous artifacts, including turned window leads and diamond-shaped window glass, were apparently recovered in the course of the excavation of the structure (Ragland 1932). Photographs of the excavations suggest that the interior of the structure was completely excavated in 1932.

Figure 13. Plan of building foundations excavated east of Bassett Hall (from Ragland 1932).

25

within the cellar was earthen. Access into the cellar was gained through a bulkhead entrance west of the southern chimney. The bulkhead had also been added after the original foundations had been constructed. Attached to the east side of the original structure was a one-and-a-half-brick-wide foundation for a two-roomed addition. Evidence of brick paving was noted in the southern room, but not in the northern room. The plan drawing also indicates a brick-lined sump along the south wall of the brick-paved room within the addition. Numerous artifacts, including turned window leads and diamond-shaped window glass, were apparently recovered in the course of the excavation of the structure (Ragland 1932). Photographs of the excavations suggest that the interior of the structure was completely excavated in 1932.

In May 1980, a portion of the foundation was re-exposed during the removal of an old oil storage tank, twelve feet north of Bassett Hall Reception Building (Building 22-B). The location of the foundation was recorded and the hole was backfilled (Archaeology Monthly Reports, May 1980).

At the time of the original excavations, based on the large size of the northern chimney, the foundations were thought to represent those of an early colonial kitchen, possibly dating to the seventeenth century (Ragland 1932). Subsequent research has hypothesized that the structure represents a two-roomed, hall-and-parlor structure possibly dating to the seventeenth century (Brown 1998:113). If the structure does date to the seventeenth century, it may represent the Middle Plantation home of James Bray I, who had built a home on the property between 1671 and 1677. In order to more conclusively determine the age and function of the structure, a re-excavation of the foundations and the surrounding area would be required employing the benefits of modern archaeological techniques of stratigraphic excavation, would be required.

Thirty feet east of the foundations, a colonial well (1-A-2) thought to be associated with the structure was identified. A photograph of the well shows evidence of square-shaped brick foundation around the well. The well was apparently excavated to a depth of 27.2 feet below grade, and the water-table within the well shaft was reached at 21.6 feet below grade. Numerous "colonial period" artifacts were reportedly also excavated from the fill within the well, and turned over to Mr. Goodwin in 1932 (Ragland 1932). In 1932, Harold R. Shurtleff, Director of the Research and Record Department at Perry, Shaw, and Hepburn, wrote regarding the well and associated building foundations, "...it looks as if we were dealing with a very old site - I should think the oldest that we have come across in Williamsburg" (Shurtleff 1932).

Other features uncovered during Ragland's cross-trenching were the remains of a double chimney base measuring 10'2" x 8'5", located approximately 330 feet south, and 190 feet east of the northeast corner of the main dwelling house. In the area immediately surrounding the double chimney base, a 34-foot-long concentration of brick fragments, and a small square pit (6' x 4' x 2.6') were identified and may be associated with the double chimney base. To the south of the main dwelling house, 270 feet south and 264 feet west of the northeast corner of the main dwelling house, a small concentration of brick and mortar, 3 feet in diameter, was detected. The location of the feature corresponds with the location of an outbuilding shown on the Frenchman's Map. No other evidence of any structures was located in the yard south of main dwelling house. Finally, the foundations of a colonial-era ice house were located 687 26 feet south and 272 feet east of the northeast corner of the main dwelling house (Ragland 1932). Photographs of the excavations indicate that the ice house was completely excavated.

No archaeological work of any kind was conducted at the Bassett Hall property after 1932 for more than forty years. In April 1973, Colonial Williamsburg archaeologists were advised of, but did not observe directly, the removal of a large boxwood off the southwest corner of the smokehouse in the rear yard. The removal produced a quantity of bottle and carboy fragments dating from the late eighteenth century found within undisturbed stratigraphy (Archaeology Monthly Reports, April 1973).

In the spring of 1980, an area of land was cleared for a new parking lot to be located east of the Bassett Hall Reception Building (Building 22-B). A surface investigation of the proposed parking lot area revealed the existence of a small graveyard containing as many as eighteen individual graves, and possibly enclosed within a post and rail fence (Figure 14). The cemetery is believed to date to prior to 1865. The position of each of the graves was recorded, although none of the graves were excavated. Also within the confines of the proposed parking area, a well was discovered 35 feet east of the Bassett Hall Reception Building. The upper portion of the well was excavated to a depth of 7 feet, revealing a well shaft that measured 9 feet (east-west) by 8 feet (north-south). A layer of dark loam, dating to the second half of the eighteenth century, capped the top of the well. Artifacts from the uppermost fill layers within the well dated to 1745-1750. The remainder of the well shaft was not excavated.

Figure 14. Plan of archaeological features within the proposed new parking lot (1980).

27

In addition, a small silt-filled erosion gully dating to the eighteenth century was also discovered, six feet north of the well. Artifacts within the gully showed evidence of having been in a fire (Archaeology Monthly Reports, May 1980).

Figure 14. Plan of archaeological features within the proposed new parking lot (1980).

27

In addition, a small silt-filled erosion gully dating to the eighteenth century was also discovered, six feet north of the well. Artifacts within the gully showed evidence of having been in a fire (Archaeology Monthly Reports, May 1980).

Monitoring of new utility lines on the Bassett Hall property in the spring of 1980 revealed an additional feature. A trash pit dating to the late eighteenth century was identified 35 feet east of the main dwelling house, during the excavation for a new utility line. No further excavation of the feature was undertaken, the location of the feature was recorded, and the utility trench backfilled (Archaeology Monthly Reports, May 1980).

No other archaeological work has been conducted within the immediate vicinity of the Bassett Hall dwelling house, yard, or gardens. The total extent of the Bassett Hall property, however, consisted of an area extending for several hundred acres beyond the house. Different portions of the extensive Bassett Hall acreage have undergone various phases of archaeological investigation ranging from none at all to complete excavation. As a result of these previous investigations, numerous archaeological sites have been identified and analyzed. For a more detailed account of the findings from these various investigations, the reader is referred to the individual site manuscripts, as their results are beyond the scope of this report (Myzk 1983; Hodges 1988; Steen 1992; Kostro 2000, 2001).

In summary, in comparison to other well-known Williamsburg properties (e.g., the Peyton Randolph House, the Brush-Everard House, Shields Tavern), Bassett Hall has undergone very limited archaeological research prior to 2001. Of the archaeological work that has been completed, the majority of the research has been conducted at the survey (Phase I) or assessment (Phase II) level, with only a limited number of salvage or data recovery projects. In addition, the majority of the previous archaeological emphasis has been on the distant portions of the property well beyond Colonial Williamsburg's Historic Area. The results of these projects has been a substantial quantity of information on the prehistoric occupations, possible slave-related sites, and tenant farm sites all located along the southern perimeter of the property. In contrast, however, very little archaeological research has been initiated on the north end of the property regarding the seventeenth- and early eighteenth-century Bray family occupation, or the late eighteenth- and early nineteenth-century Johnson and Bassett occupations and plantation operations. What little work has been completed prior to 2001 was limited to either cross-trenching in 1932, or monitoring of new parking lot and utility line installations in the 1980s and 1990s.

28Chapter 3.

Archaeology in 2001

Research Design/Methods

In anticipation of the waterproofing project, the Department of Archaeological Research conducted an archaeological investigation of the areas around the exterior of Bassett Hall to be impacted by the waterproofing (Figure 15). As part of the investigation, two-meter-wide trenches were hand excavated along the structure's north elevation, around the chimneys on the structure's east and west gable ends, and along the east of dining room wing addition. Along the west elevation of the dining room wing, a three-and-a-half meter wide trench was excavated to correspond with a larger area of impact as indicated by the waterproofing plans. In areas of extensive disturbance as a result of utility lines, tree plantings, or previous waterproofing, no excavation was undertaken, as it was presumed that that very little archaeological data had survived in these areas. In addition, no investigation was made along modern kitchen wing attached to the rear of structure. No intact archaeological resources were thought to have survived within the area of the kitchen wing due to construction activity in the early 1930s. To further facilitate the excavations, several large boxwoods were removed from around the north and west elevations of the building prior to the start of the fieldwork. In addition, along the west elevation of the dining room wing, a large (9.65 x 3.75 m) brick terrace was also removed.

Figure 15. Locations of archaeological trenches around Bassett Hall in 2001.

Figure 15. Locations of archaeological trenches around Bassett Hall in 2001.

Both horizontal and vertical controls were employed over the excavation of the trenches around Bassett Hall. Horizontal control was achieved via a Cartesian grid, placed at one-meter intervals across the site, and aligned with the town grid. Each grid square was identified by the north and east coordinates of the northwest corner of the grid square. For record keeping purposes, each separate soil layer or distinctive feature within the excavation area was assigned its own unique context number by which it could be identified. In order to maintain vertical control over the site, each soil layer or feature was stratigraphically excavated, using shovels and trowels, following the natural contours and boundaries of the layers and features. Differentiation between the different layers and features were recognized by changes in soil type, color or texture. All pre-restoration soils were passed through one-quarter-inch mesh screens to recover any artifacts. In the field, each soil layer or feature was mapped, photographed, and described in detail. Detailed notes were recorded for every context using Hewlett Packard Jornada 680 and Hewlett Packard Jornada 820 handheld computers. All field records were downloaded from the handheld computers into Re:Discovery, the collections management computer database used the by D.A.R.

All of the excavated artifacts were bagged by context and sent to the laboratory for processing and analysis. At the lab, the artifacts were washed, identified, and inventoried according to provenience. The artifacts were inventoried using a standard descriptive typology with all obvious functional and morphological characteristics noted, and entered into Re:Discovery. Based on this, each context was assigned a terminus post quem (TPQ), using the artifact with the most recent first manufacture date. The TPQ date represents the date after which the context was deposited. All of the field documentation, artifacts, and artifact information recovered during the fieldwork, and the subsequent laboratory documentation, are currently stored at the D.A.R. Laboratory.

Research Results